Dec 3, 2025

Fashion teams work with tight timelines, shifting demand, and vendors spread across different regions.

Factories manage multiple clients, materials change late in the season, and every update affects fit, cost, and delivery. A single missed detail can slow a style down or create avoidable rework for both sides.

Strong vendor relationships shape the quality of every collection. When communication feels scattered, factories guess instead of knowing.

When expectations are clear, work moves faster, and everyone involved feels more confident in what needs to happen next.

Vendor relationship management (VRM) gives your team a practical way to keep those relationships organized.

It brings clarity to daily communication, approvals, and sample feedback, and it helps both sides work in a way that feels respectful, consistent, and predictable.

In this article, you’ll see how VRM supports your work with factories each season, how it influences product quality and timelines, and how modern tools like Onbrand help your team keep information in one place.

TL;DR

Vendor relationship management in fashion organizes communication and daily workflows with factories and suppliers.

Clear processes help teams move samples faster, reduce errors, and improve product quality.

Keeping tech packs, updates, and approvals in one place prevents issues caused by outdated files or scattered emails.

PLM systems support VRM by centralizing styles, materials, timelines, and comments for both teams and factories.

Onbrand PLM and Onbrand AI Design streamline alignment, reduce rework, and help factories receive clearer direction.

What Is Vendor Relationship Management In Fashion?

VRM is the way your team organizes communication, expectations, and day-to-day work with factories, mills, trim suppliers, and agents.

It covers the full flow of tech packs, samples, fit notes, approvals, and delivery updates that shape each collection.

Fashion brands and companies rely on multiple suppliers, each with different strengths, lead times, and quality standards.

Clear vendor relationships help both the buyer and the factory understand what needs to happen next, which supports timely delivery and fewer surprises during development.

A vendor handles cut-and-sew work, materials, trims, or specialty services, while a supplier may focus on fabrics, components, or upstream parts of the supply chain.

In most fashion teams, both roles overlap, which makes clear relationship management important for keeping styles on track.

Strong VRM goes beyond contracts or price discussions. It influences how smooth the season feels, how fast samples move, and how easy it is for both sides to maintain a healthy working rhythm.

Effective vendor management creates a healthy vendor relationship built on clarity, consistent communication, and mutual trust each season.

Why Vendor Relationship Management Matters for Every Collection

Strong vendor partnerships shape how smoothly each season comes together and support long-term business strategy across categories. Clear communication keeps teams aligned, while scattered updates slow decisions and create unnecessary rework.

Fashion teams see the biggest impact in day-to-day development:

Faster sample cycles and fewer remake rounds

Fewer production mistakes because factories work with current information

Stronger product quality across categories

A clearer view of costs, lead times, and capacity during assortment planning

Better support for sustainability and compliance efforts

These gains help your team keep collections on time, protect margins, and give factories clarity around what they need to deliver.

Effective vendor relationship management also stabilizes work when supply chain disruptions put pressure on timelines.

Fashion brands often work with multiple vendors, and even small gaps in communication can affect fit, consistency, or product quality.

A simple vendor relationship management process helps teams stay aligned and introduces numerous benefits for development and communication. These habits strengthen supplier relationships, create a more predictable flow during development, and build healthier long-term patterns for managing vendors.

Core Vendor Relationship Workflows in Fashion

Fashion teams move through fast seasons, shifting priorities, and constant design updates. These workflows affect how well your team and vendors stay connected during development.

Sharing Tech Packs and Clarifications

Sending PDFs or spreadsheets often leads to version issues. Vendors open old files, miss updated sketches, or follow outdated measurements.

Live tech packs keep everything in one place and support accurate product data management, which helps maintain clear vendor relations and stable communication across supply chains.

This structure gives factories the confidence to work without second-guessing details.

Costing, MOQs, and Lead Time Discussions

Sourcing teams talk through pricing, MOQ breaks, fabric options, and delivery windows with each factory.

Clear records help teams review past decisions, check supplier performance, and avoid surprises that affect margins.

These habits reflect strong vendor management best practices that procurement teams often use to support long-term relationships.

Sample, Fit, and Lab Dip Rounds

Samples move fast during the season. Fit notes, photos, pattern changes, and approvals sit inside one record instead of spreading across emails.

Color sign-offs, lab dips, and material updates stay connected to each style, which supports cleaner garment quality control from development through production.

Compliance, Certifications, and Quality Expectations

Factories receive testing standards, certifications, safety documents, and compliance requirements in one space.

Keeping everything attached to styles helps teams address potential risks early and makes it easier to maintain consistent compliance across categories.

Performance and Long-Term Partnership Decisions

Instead of formal supplier scorecards, fashion teams look at consistency, reliability, fit accuracy, and communication across the season.

These touchpoints help your team understand a vendor’s performance, identify strategic vendors, and factor in financial stability when deciding who receives more styles next season.

The goal is a healthy, mutually supportive way of managing relationships that strengthens vendor leads and creates smoother production across seasons.

Vendor Relationship Management Best Practices For Fashion Teams

Strong vendor work grows from habits that keep your communication clear and predictable. You move through fast seasons, handle shifting priorities, and need a process that supports healthy relationships without adding unnecessary steps.

A structured approach gives your team a calmer rhythm with factories and suppliers. It also helps maintain product quality and steady progress during every stage of development.

Key practices include:

Treat key vendors as long-term partners. A healthy relationship shapes smoother development and strengthens customer trust.

Share early forecasts when possible. Even rough estimates help factories plan capacity across supply chains and prevent avoidable delays.

Keep instructions inside one workspace. Centralized updates support cleaner supplier management and more accurate specification management.

Confirm agreements inside your product system. Clear records help you manage contract terms, vendor payment terms, and performance monitoring without chasing scattered messages.

Give constructive feedback after major rounds. You gain valuable insights into vendors’ performance while encouraging continuous improvement.

Document decisions that affect style details or timing. New team members and new vendor contacts understand context without searching through old threads.

These habits support risk mitigation, cost control, long-term success, and better customer satisfaction as your collections grow.

How PLM Supports Vendor Relationship Management

A product lifecycle management (PLM) system gives your team one organized place to handle styles, materials, BOMs, size runs, and timelines.

Vendors see current tech packs rather than outdated files, which helps them deliver accurate samples and meet agreed-upon standards. Every detail stays linked to the correct style, and comments or approvals stay visible without extra searching.

When your team works inside one structured system, you gain clearer progress across supply chain management. Updates move faster, and you avoid gaps that lead to missed information or repeated work.

A structured workspace also supports stronger alignment with potential suppliers, since your direction, measurements, and references stay consistent.

A reliable PLM setup helps your team control costs and streamline processes that depend on clear vendor communication.

It supports risk management through traceable updates, which helps you handle risk assessment during busy development periods. Vendor selection becomes easier when you can review how partners handle feedback, sample timing, and quality expectations.

You gain a smoother path through each season, and vendors work with confidence because the information they receive stays organized.

Onbrand: The Workspace That Helps Your Team Collaborate With Vendors Faster

Fashion teams need a system that keeps vendor work clear, organized, and easy to follow.

When every update connects to the right style, and every comment lives in one place, factories move with more confidence, and your schedules stay on track.

Onbrand gives your team the structure to keep vendor communication simple and predictable, even when changes happen late in product development.

Two connected tools support that workflow.

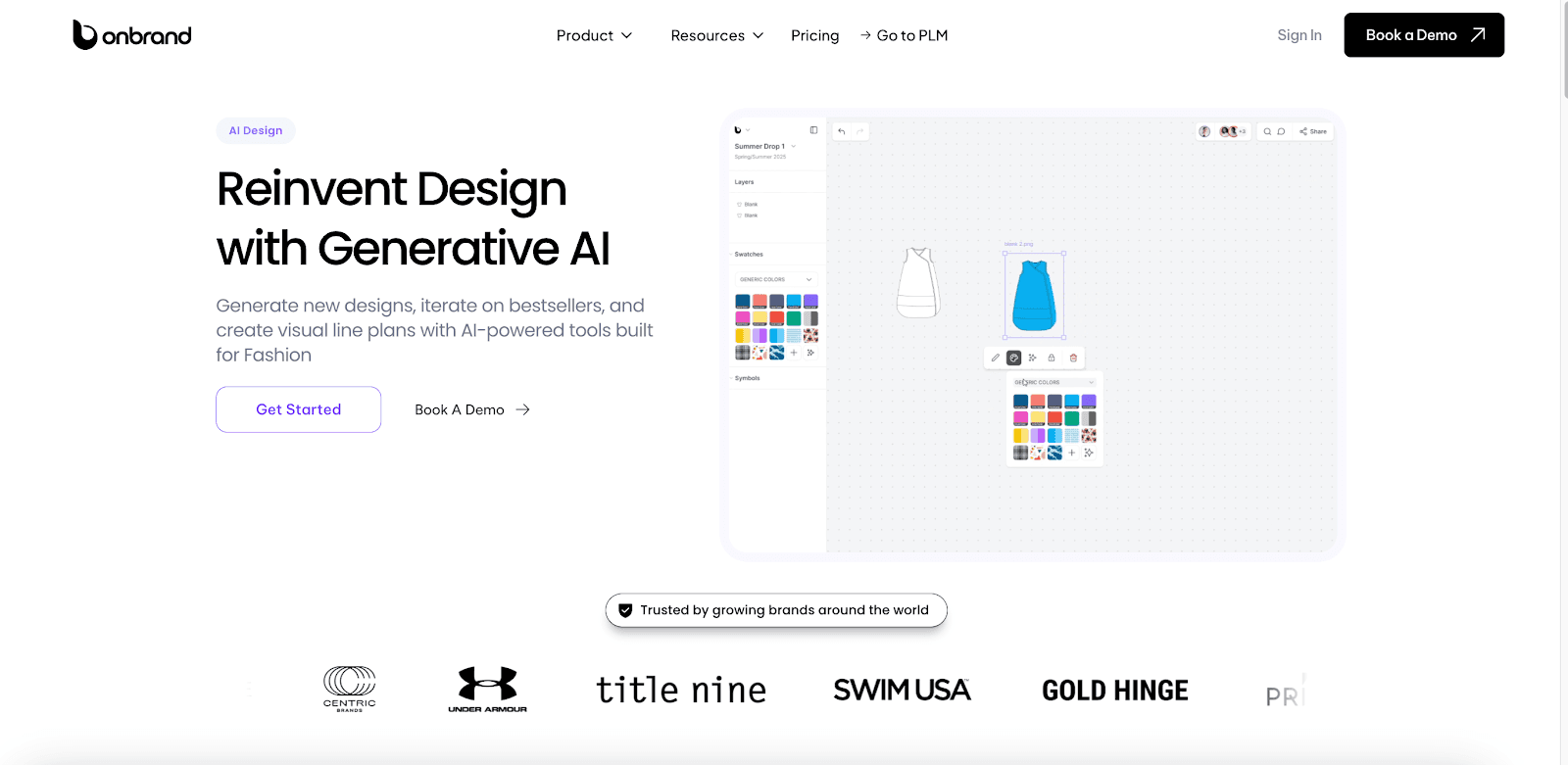

Onbrand PLM gives your team a shared space for styles, materials, tech packs, timelines, and approvals. Onbrand AI Design strengthens early creative alignment, which helps factories receive cleaner briefs and reduces confusion later in the season.

How Onbrand PLM Helps You Work Better With Vendors

Onbrand PLM replaces scattered files with a streamlined workspace that keeps factories aligned with your team.

You gain clear visibility across styles and seasons, vendors receive up-to-date information, and development speeds up.

Brands using Onbrand report 55% faster tech pack creation, a 4-week reduction in development time, and 10-day onboarding with full data migration.

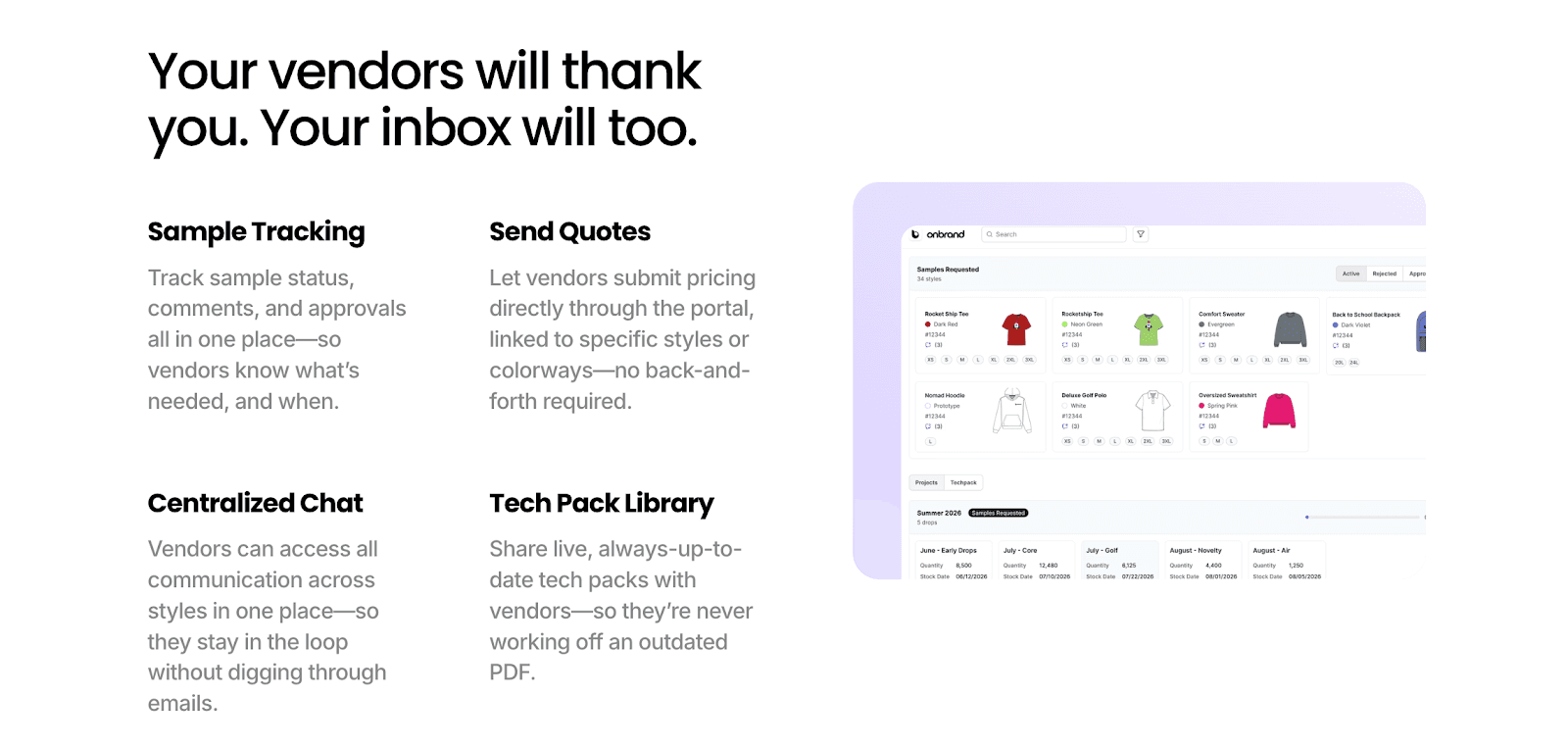

Key features that support vendor collaboration:

Live tech packs – Vendors always view the current version without sorting through old PDFs or email threads.

In-context comments – Feedback sits next to the exact field or measurement vendors need to review.

Vendor logins – Factories can check styles, samples, and updates without waiting for email attachments.

Dedicated material and trim libraries – Vendors follow approved fabrics, colors, and artwork without guesswork.

Project views – Seasonal status pages help teams monitor progress across categories and respond early to issues.

Onbrand PLM adapts to your existing process, removes extra steps, and cuts down on the constant “Can you resend that?” messages that delay development.

How Onbrand AI Design Sets a Clear Direction Before Vendors Start

Onbrand AI Design helps your team agree on style direction before briefs reach factories.

Clean mood boards, organized concepts, and clear color direction make early alignment easier, which limits revisions once development begins. You provide vendors with stronger briefs that capture the details they need.

Key features that support early clarity:

Visual concept boards – Organize inspiration, color ideas, and silhouette direction in one space.

Automated sketch and design tools – Produce clean visuals that help vendors read your requirements.

Real-time creative collaboration – Designers and category managers align quickly before sending anything to factories.

Easy handoff to PLM – Designs move directly into Onbrand PLM without rework or file chasing.

Early clarity reduces confusion later, which helps factories move faster and limits unnecessary revisions.

Getting Started With Vendor Relationship Management

A simple starting point works best. Pick one or two key vendors and test a more organized structure with them first. You give your team space to learn what feels helpful and what creates smoother teamwork.

It also helps you spot early wins that support business growth without adding pressure. Move all tech packs, comments, and sample notes into Onbrand PLM for that small group.

Centralizing updates creates one reliable location for every detail and removes the confusion caused by scattered messages.

This kind of setup is similar to customer relationship management (CRM), but built for your vendor partnerships and daily product work.

Set clear expectations together. Agree on where feedback lives, how service level agreements fit into your process, and what each side needs for a win-win partnership. Vendors appreciate knowing where to look, and your team gains more predictable communication.

At the end of the season, review your progress. Look at accuracy, speed, and the volume of chaser messages avoided. You can also check simple key performance indicators, such as fewer sample corrections or stronger alignment on measurements.

Most teams notice early signs of cost savings as back-and-forth steps drop and processes are streamlined across styles.

Improve How Your Team Works With Vendors Using Onbrand

Vendor relationships shape the pace, quality, and confidence behind every collection your team delivers. When communication stays clear, and every update lives in one place, factories move with accuracy, and your seasons feel smoother from development through production.

Onbrand PLM gives your team that structure. You gain live tech packs, organized feedback, and one shared workspace that keeps vendors aligned at every stage.

Onbrand AI Design adds clarity even earlier in the process, helping your team lock direction before briefs reach factories, which reduces confusion and sets cleaner expectations from day one.

If you're ready to bring vendor communication into one reliable system, book a demo and see how it helps your team work with factories faster and with far fewer steps.

FAQs About Vendor Relationship Management

What is the difference between CRM and VRM?

CRM focuses on customers, while VRM organizes factory communication, sample work, approvals, and product updates. VRM helps teams keep production on track, manage contractual obligations, and mitigate risk across suppliers. CRM improves sales and support workflows, while VRM supports development accuracy and smoother collaboration.

How do you maintain relationships with vendors?

Clear expectations, consistent updates, and one organized workspace help maintain strong vendor communication. Fashion teams review timing, quality, and pricing in one place, support joint planning, and address issues early to avoid cash flow problems. Healthy communication builds a mutually beneficial relationship that feels predictable for both sides.

What are the 5 key points of SRM?

SRM often includes onboarding, performance tracking, communication, improvement plans, and long-term partnership development. These steps guide overseeing relationships, help teams mitigate risk, support stronger strategic alliances, and create steady paths toward lower costs and reliable production.

What is it like to be a vendor relationship manager?

The role focuses on communication, accuracy, and partnership-building with factories and mills. A manager tracks updates, handles reviews, aligns on business needs, and resolves production concerns quickly. They also manage details tied to exclusive contracts, pricing, quality, and financial instability, using structured systems or software solutions to stay organized.