How Specification Management Software Helps Fashion Brands

How Specification Management Software Helps Fashion Brands

Feb 3, 2026

Fashion brands balance tight deadlines, short trend cycles, global supply chains, and growing pressure to deliver more sustainable products as the business scales.

Designing great styles is only one part of the work. Getting measurement details right helps avoid costly mistakes and keeps production moving without delays.

That’s where specification management software comes in.

It keeps product data in one place, helps reduce mistakes, and gives designers, developers, and vendors access to the same up-to-date information.

In this guide, we break down what specification management is, how it supports fashion production workflows, and why the right software helps you save time, reduce stress, and experience fewer delays from start to finish.

TL;DR

Specification management software helps fashion brands manage fit, sizing, and measurement data in one place to support accurate samples and smoother production.

Core specs include Points of Measure, size charts, tolerances, grade rules, and how-to-measure guides, which factories use to review samples and request revisions.

Using software instead of spreadsheets reduces version confusion, miscommunication, and rework during fit rounds and vendor handoffs.

Onbrand PLM supports specification management with live tech packs, version control, and vendor collaboration, with Onbrand AI Design helping align concepts before specs move into PLM.

What Is Specification Management in Fashion?

In the fashion industry, specification management means clearly documenting and managing garment measurements to support accurate fit and consistent sizing. The process plays a central role in technical design and guides factories through sample creation and final production.

Specification management includes:

Points of Measure (PoMs) – Specific garment measurements such as chest width, sleeve length, or neckline depth.

Size charts – Measurements listed by size (XS–XXL).

Fit tolerances – Acceptable variations in measurements (for example, chest width ±0.5”).

Grade rules – How measurements scale across sizes.

How-to-measure guides – Visual instructions showing exactly how and where each measurement is taken, such as chest width measured 1” below the armhole.

Specifications usually appear as tables, with PoMs listed vertically and sizes shown horizontally. Factories reference these measurements and guides as preparation instructions to check samples against approved specs. If a sample falls outside tolerance, revisions are required.

Specifications are one part of the broader tech pack, alongside documents such as Bills of Materials (BOMs), construction notes, and packaging or compliance guidelines. Together, they help products meet brand quality standards from concept through production.

How Specification Management Software Helps Fashion Brands

Product specification management software helps you manage fit-related data with greater speed, data accuracy, and control to support data-driven decisions.

Instead of relying on static spreadsheets, you can build, update, and share measurement specs with real-time updates in one platform.

The software supports sample management across the entire lifecycle, from early fit reviews through production. You can log Points of Measure, update size charts, apply tolerances, and upload how-to-measure visuals in one place.

When specs change, everyone sees the update immediately. This reduces miscommunication between technical design, development, and factory partners and helps maintain consistency across fit rounds and production runs.

Version control also plays an important role. You can track edits, compare changes, and return to earlier versions when needed, which is especially helpful during multiple fit revisions or vendor submissions.

While the focus stays on measurement accuracy, many specification systems connect with tools that manage BOMs, raw materials, construction notes, and packaging requirements. Connecting these tools supports a more connected development process while keeping specs clear and easy to manage.

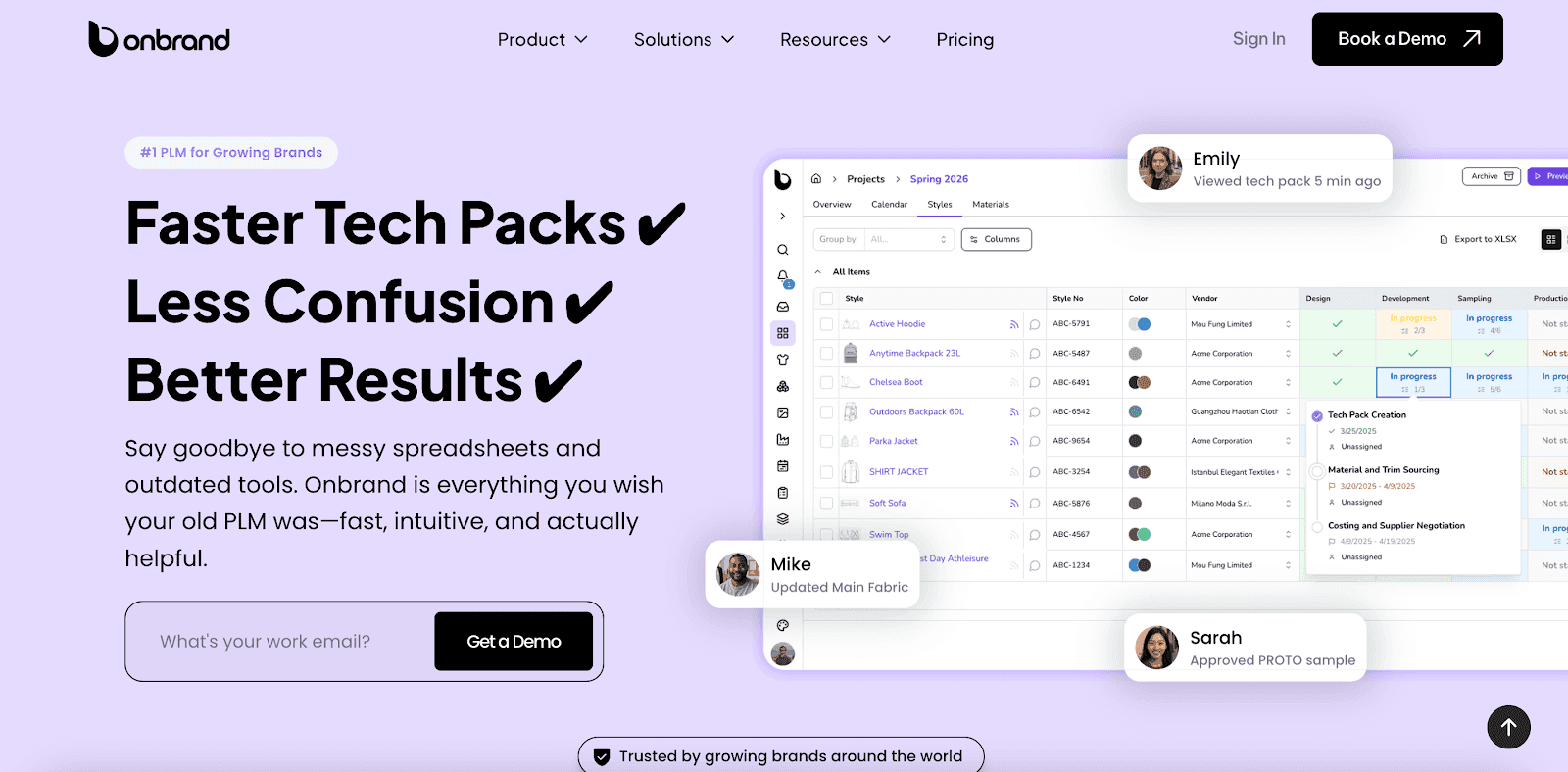

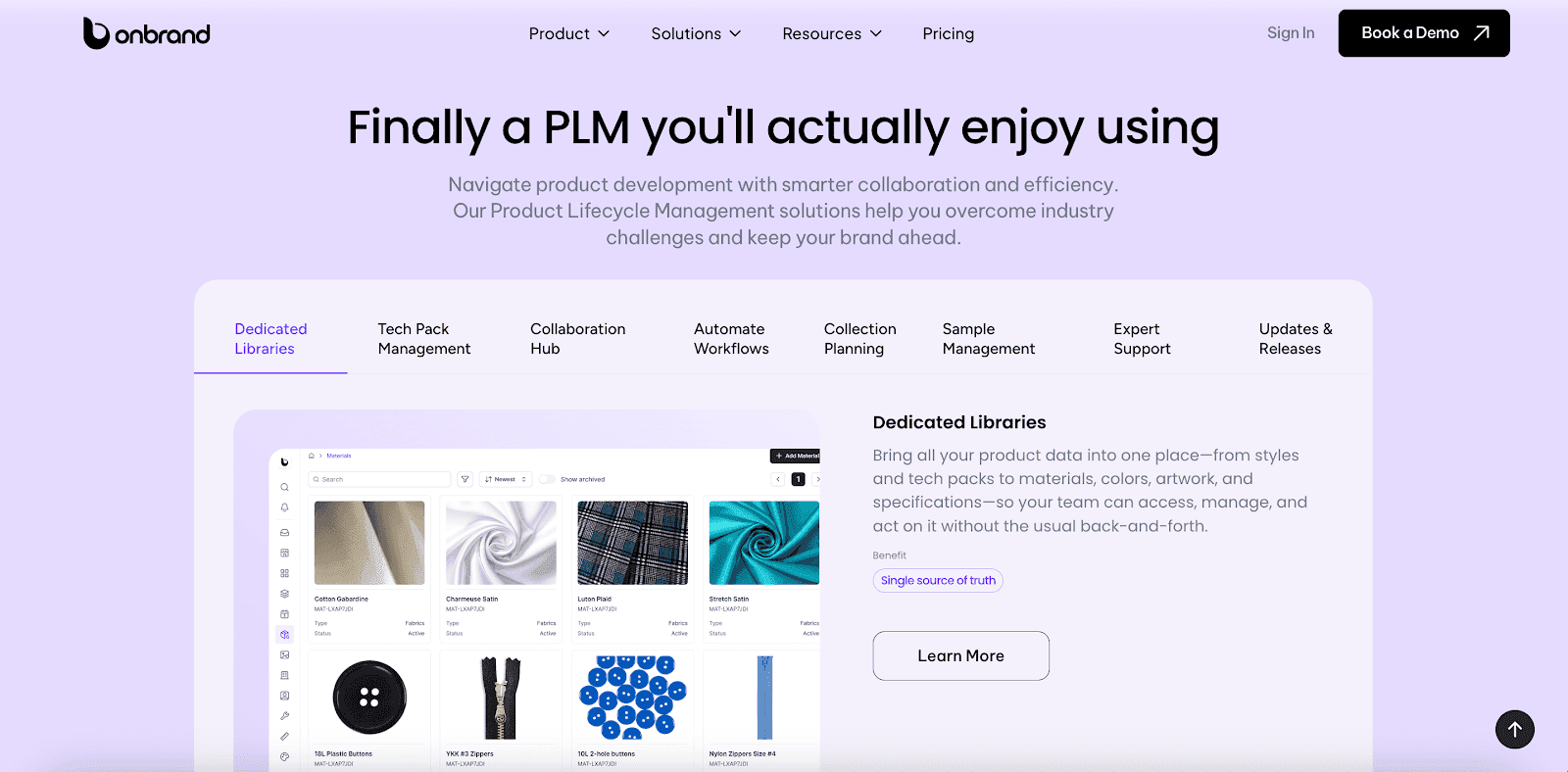

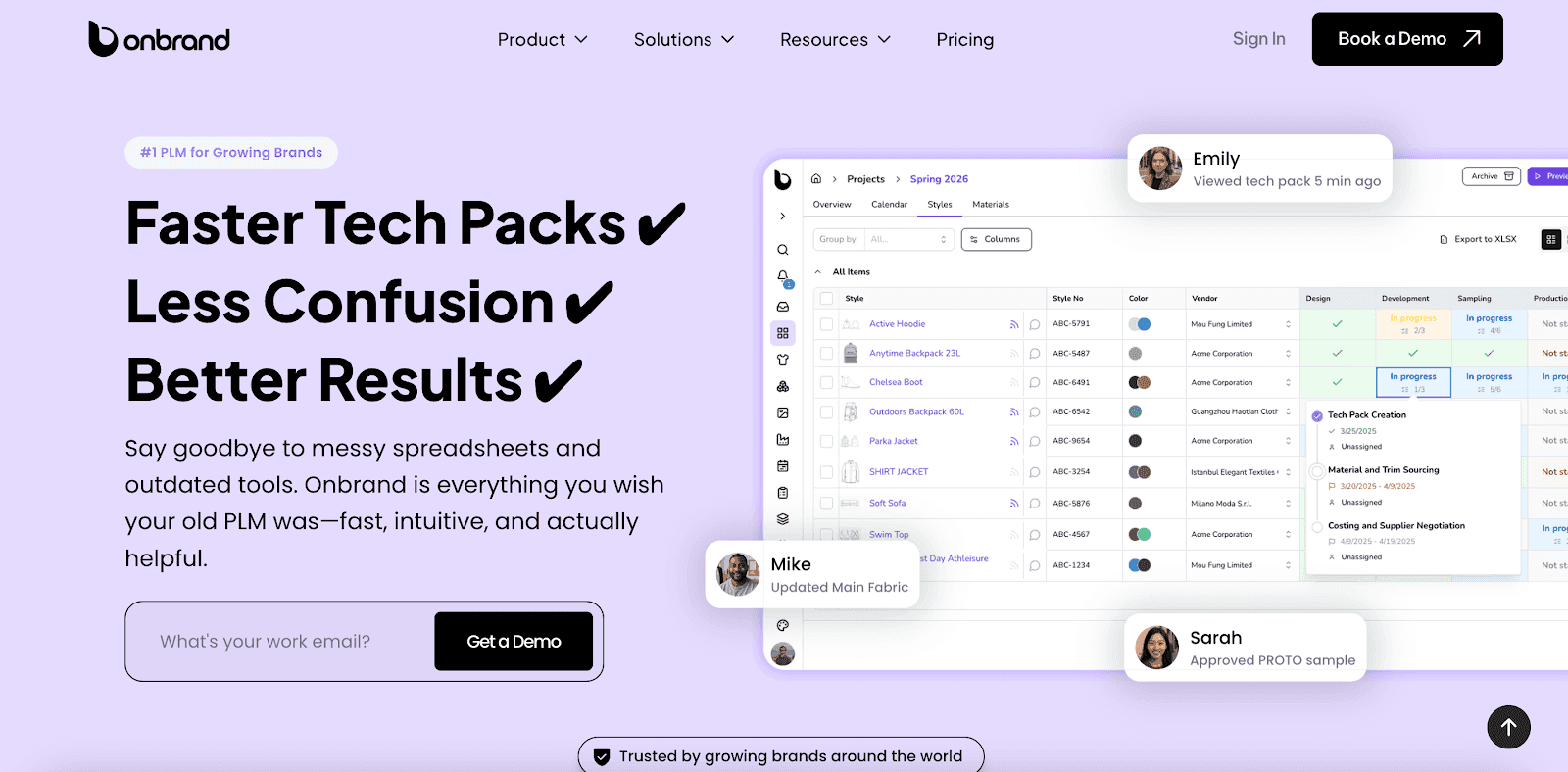

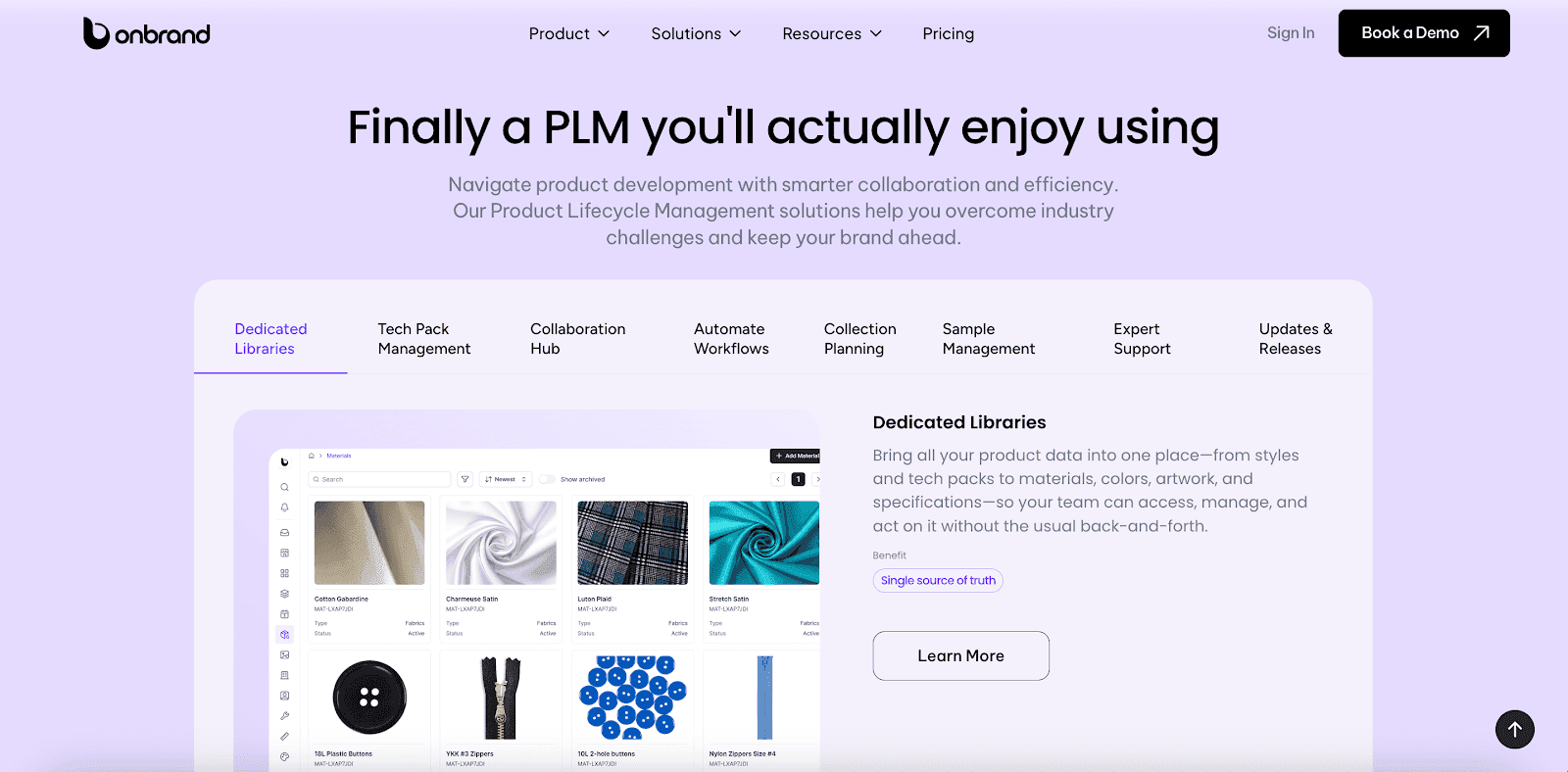

Onbrand PLM: Specification Management Software Built for Modern Fashion Teams

Fashion production moves quickly, and outdated PLM systems slow you down. Onbrand PLM is specification management software built for growing fashion brands.

It replaces spreadsheets, static tech packs, and clunky legacy solutions with one easy-to-use platform your whole team will actually enjoy using.

Onbrand PLM lets you manage every product detail, such as fabrics, trims, fit notes, packaging, and compliance, in one place.

Live tech packs function like Google Docs, so updates are instant, and everyone always sees the latest version. Brands using Onbrand PLM have cut tech pack creation time by over 55% and reduced development timelines by up to 4 weeks.

You also get built-in project management, real-time vendor collaboration, and fast, flexible onboarding. While legacy PLMs can take 6 to 24 months to implement, Onbrand customers are fully live in just 2 to 4 weeks, including AI-powered data migration, full setup, and team training.

Unlike legacy tools that charge for upgrades and support, Onbrand is true SaaS. Updates roll out automatically to all customers, and there are no hidden service fees.

It's faster, more intuitive, and costs less than half of most legacy platforms.

For earlier design stages, Onbrand also offers AI Design, which helps teams explore concepts and align on direction before styles move into PLM-managed tech packs and specifications.

Top Benefits of Specification Management Software for Fashion

Comprehensive specification management software helps you stay organized, keep work moving, and reduce common production mistakes. Here’s how it supports day-to-day work.

Helps Teams Work Better Together

Fashion projects involve many roles, including designers, developers, vendors, suppliers, and production managers.

With specs stored in a shared centralized database, digital document management becomes easier because everyone works from the same information. That cuts down on email chains, file confusion, and questions about which version is approved, lowering risk during fit rounds.

When teams use a shared platform, there’s less confusion about changes, updates, or approvals. Everyone stays aligned, no matter where they’re working from.

Improves Product Quality

Good specs lead to good products. When technical specs like PoMs, grade rules, and fit tolerances are documented clearly, teams can create more accurate samples and reduce costly errors during production.

The software helps your team identify issues early, reduce errors, and keep every version of the product on track.

That means fewer returns and higher quality products, which strengthens quality management, improves customer satisfaction, and protects your brand reputation.

Makes Compliance Easier

When measurement tolerances are clearly documented, it's easier to evaluate whether samples meet brand standards for fit and maintain compliance.

Specification software gives teams clarity and consistency by reinforcing clear measurement practices, reducing the chances of off-spec garments reaching production.

Instead of chasing documentation late in the process, you have the information ready during new product development. That helps you meet compliance requirements and avoid unnecessary delays or penalties.

Supports Sustainable Choices

Many fashion companies want to use better materials, reduce waste, or track sourcing. Specification management software gives teams a clear view of what’s being used and where it’s coming from.

That kind of visibility helps with more sustainable decisions. It also supports supply chain transparency by making data easy to review and share.

Speeds Up the Process

Without a proper system, teams spend too much time searching for files or fixing issues that could’ve been avoided, wasting valuable resources. This software keeps everything clear and easy to update.

When specs are organized and accessible, your team can work faster and improve efficiency at every stage of development.

How Fashion Teams Use Specification Management Software

Specification management software can help fashion teams across several important areas. Here are some practical examples of how different teams use it every day:

Product Specification Management

You can manage Points of Measure, size charts, grade rules, and fit tolerances in one place. When these are documented clearly, factories can deliver accurate samples, and fewer revisions are needed.

With product specifications clearly recorded, teams can avoid misunderstandings and ensure the final garment matches the original design.

Tech Pack Integration: BOM and Compliance Data

While BOMs and compliance data live outside measurement specs, many platforms allow you to connect these systems. This setup supports a more unified product development workflow without crowding the specification process itself.

Measurement and Fit Management

Specification software gives technical designers a structured way to define every Point of Measure.

You can build detailed spec tables with size charts from XS to XXL, clear measuring instructions, and acceptable tolerance ranges.

For example, chest width may be measured one inch below the armhole with a tolerance of plus or minus 0.5 inches.

When measurement charts and visual guides are included in the tech pack, factories have clear manufacturing instructions for checking samples.

Clear instructions reduce miscommunication, shorten development cycles, and improve first-sample accuracy.

Manage Your Fashion Production in One Place With Onbrand

Clear, well-managed specifications are the foundation of fashion production. When you have easy access to up-to-date spec data, it becomes easier to stay on schedule, maintain product quality, and meet regulatory compliance standards as requirements change.

Onbrand PLM gives fashion brands a clear way to manage specification data across the fashion product development process. With one connected platform, you can track updates, reduce errors, and keep design and production on the same page.

For brands that want continuity from early concepts through production, Onbrand also offers AI Design to support concept exploration before styles move into PLM-managed tech packs and specifications.

FAQs About Specification Management Software

What is a specification manager?

A specification manager keeps product details accurate, organized, and ready for production. In fashion, that means helping teams share specs, avoid manual work, and stay aligned with quality standards, industry standards, and regulatory compliance. It’s a hands-on role that supports smooth project execution and cuts down on quality issues and communication breakdowns.

How does specification management support quality and sustainability goals?

Great specs lead to better products. With the right system, teams can manage fit consistency and measurement accuracy in one place. This leads to higher quality samples and fewer revisions, helping reduce waste and support broader sustainability goals.

Why do fashion brands need a centralized specification platform?

A single source of truth saves time and stress. Centralizing all the data gives teams quick access to everything they need, no more email threads or file-hunting. It also improves document sharing, supports better collaboration, and lowers risk. Fashion brands that want to deliver high-quality finished goods and scale their business need the ability to manage specs according to necessary standards, especially in fast-moving markets.

When should fashion brands invest in specification management software?

Fashion brands should invest when growing collections, expanding vendor networks, or stricter regulatory requirements make manual tracking harder to manage. As stakeholders get involved, strong document control and security become necessary to protect sensitive product data and maintain consistency. Investing early supports smoother collaboration, fewer errors, and long-term production success as the business scales.

Fashion brands balance tight deadlines, short trend cycles, global supply chains, and growing pressure to deliver more sustainable products as the business scales.

Designing great styles is only one part of the work. Getting measurement details right helps avoid costly mistakes and keeps production moving without delays.

That’s where specification management software comes in.

It keeps product data in one place, helps reduce mistakes, and gives designers, developers, and vendors access to the same up-to-date information.

In this guide, we break down what specification management is, how it supports fashion production workflows, and why the right software helps you save time, reduce stress, and experience fewer delays from start to finish.

TL;DR

Specification management software helps fashion brands manage fit, sizing, and measurement data in one place to support accurate samples and smoother production.

Core specs include Points of Measure, size charts, tolerances, grade rules, and how-to-measure guides, which factories use to review samples and request revisions.

Using software instead of spreadsheets reduces version confusion, miscommunication, and rework during fit rounds and vendor handoffs.

Onbrand PLM supports specification management with live tech packs, version control, and vendor collaboration, with Onbrand AI Design helping align concepts before specs move into PLM.

What Is Specification Management in Fashion?

In the fashion industry, specification management means clearly documenting and managing garment measurements to support accurate fit and consistent sizing. The process plays a central role in technical design and guides factories through sample creation and final production.

Specification management includes:

Points of Measure (PoMs) – Specific garment measurements such as chest width, sleeve length, or neckline depth.

Size charts – Measurements listed by size (XS–XXL).

Fit tolerances – Acceptable variations in measurements (for example, chest width ±0.5”).

Grade rules – How measurements scale across sizes.

How-to-measure guides – Visual instructions showing exactly how and where each measurement is taken, such as chest width measured 1” below the armhole.

Specifications usually appear as tables, with PoMs listed vertically and sizes shown horizontally. Factories reference these measurements and guides as preparation instructions to check samples against approved specs. If a sample falls outside tolerance, revisions are required.

Specifications are one part of the broader tech pack, alongside documents such as Bills of Materials (BOMs), construction notes, and packaging or compliance guidelines. Together, they help products meet brand quality standards from concept through production.

How Specification Management Software Helps Fashion Brands

Product specification management software helps you manage fit-related data with greater speed, data accuracy, and control to support data-driven decisions.

Instead of relying on static spreadsheets, you can build, update, and share measurement specs with real-time updates in one platform.

The software supports sample management across the entire lifecycle, from early fit reviews through production. You can log Points of Measure, update size charts, apply tolerances, and upload how-to-measure visuals in one place.

When specs change, everyone sees the update immediately. This reduces miscommunication between technical design, development, and factory partners and helps maintain consistency across fit rounds and production runs.

Version control also plays an important role. You can track edits, compare changes, and return to earlier versions when needed, which is especially helpful during multiple fit revisions or vendor submissions.

While the focus stays on measurement accuracy, many specification systems connect with tools that manage BOMs, raw materials, construction notes, and packaging requirements. Connecting these tools supports a more connected development process while keeping specs clear and easy to manage.

Onbrand PLM: Specification Management Software Built for Modern Fashion Teams

Fashion production moves quickly, and outdated PLM systems slow you down. Onbrand PLM is specification management software built for growing fashion brands.

It replaces spreadsheets, static tech packs, and clunky legacy solutions with one easy-to-use platform your whole team will actually enjoy using.

Onbrand PLM lets you manage every product detail, such as fabrics, trims, fit notes, packaging, and compliance, in one place.

Live tech packs function like Google Docs, so updates are instant, and everyone always sees the latest version. Brands using Onbrand PLM have cut tech pack creation time by over 55% and reduced development timelines by up to 4 weeks.

You also get built-in project management, real-time vendor collaboration, and fast, flexible onboarding. While legacy PLMs can take 6 to 24 months to implement, Onbrand customers are fully live in just 2 to 4 weeks, including AI-powered data migration, full setup, and team training.

Unlike legacy tools that charge for upgrades and support, Onbrand is true SaaS. Updates roll out automatically to all customers, and there are no hidden service fees.

It's faster, more intuitive, and costs less than half of most legacy platforms.

For earlier design stages, Onbrand also offers AI Design, which helps teams explore concepts and align on direction before styles move into PLM-managed tech packs and specifications.

Top Benefits of Specification Management Software for Fashion

Comprehensive specification management software helps you stay organized, keep work moving, and reduce common production mistakes. Here’s how it supports day-to-day work.

Helps Teams Work Better Together

Fashion projects involve many roles, including designers, developers, vendors, suppliers, and production managers.

With specs stored in a shared centralized database, digital document management becomes easier because everyone works from the same information. That cuts down on email chains, file confusion, and questions about which version is approved, lowering risk during fit rounds.

When teams use a shared platform, there’s less confusion about changes, updates, or approvals. Everyone stays aligned, no matter where they’re working from.

Improves Product Quality

Good specs lead to good products. When technical specs like PoMs, grade rules, and fit tolerances are documented clearly, teams can create more accurate samples and reduce costly errors during production.

The software helps your team identify issues early, reduce errors, and keep every version of the product on track.

That means fewer returns and higher quality products, which strengthens quality management, improves customer satisfaction, and protects your brand reputation.

Makes Compliance Easier

When measurement tolerances are clearly documented, it's easier to evaluate whether samples meet brand standards for fit and maintain compliance.

Specification software gives teams clarity and consistency by reinforcing clear measurement practices, reducing the chances of off-spec garments reaching production.

Instead of chasing documentation late in the process, you have the information ready during new product development. That helps you meet compliance requirements and avoid unnecessary delays or penalties.

Supports Sustainable Choices

Many fashion companies want to use better materials, reduce waste, or track sourcing. Specification management software gives teams a clear view of what’s being used and where it’s coming from.

That kind of visibility helps with more sustainable decisions. It also supports supply chain transparency by making data easy to review and share.

Speeds Up the Process

Without a proper system, teams spend too much time searching for files or fixing issues that could’ve been avoided, wasting valuable resources. This software keeps everything clear and easy to update.

When specs are organized and accessible, your team can work faster and improve efficiency at every stage of development.

How Fashion Teams Use Specification Management Software

Specification management software can help fashion teams across several important areas. Here are some practical examples of how different teams use it every day:

Product Specification Management

You can manage Points of Measure, size charts, grade rules, and fit tolerances in one place. When these are documented clearly, factories can deliver accurate samples, and fewer revisions are needed.

With product specifications clearly recorded, teams can avoid misunderstandings and ensure the final garment matches the original design.

Tech Pack Integration: BOM and Compliance Data

While BOMs and compliance data live outside measurement specs, many platforms allow you to connect these systems. This setup supports a more unified product development workflow without crowding the specification process itself.

Measurement and Fit Management

Specification software gives technical designers a structured way to define every Point of Measure.

You can build detailed spec tables with size charts from XS to XXL, clear measuring instructions, and acceptable tolerance ranges.

For example, chest width may be measured one inch below the armhole with a tolerance of plus or minus 0.5 inches.

When measurement charts and visual guides are included in the tech pack, factories have clear manufacturing instructions for checking samples.

Clear instructions reduce miscommunication, shorten development cycles, and improve first-sample accuracy.

Manage Your Fashion Production in One Place With Onbrand

Clear, well-managed specifications are the foundation of fashion production. When you have easy access to up-to-date spec data, it becomes easier to stay on schedule, maintain product quality, and meet regulatory compliance standards as requirements change.

Onbrand PLM gives fashion brands a clear way to manage specification data across the fashion product development process. With one connected platform, you can track updates, reduce errors, and keep design and production on the same page.

For brands that want continuity from early concepts through production, Onbrand also offers AI Design to support concept exploration before styles move into PLM-managed tech packs and specifications.

FAQs About Specification Management Software

What is a specification manager?

A specification manager keeps product details accurate, organized, and ready for production. In fashion, that means helping teams share specs, avoid manual work, and stay aligned with quality standards, industry standards, and regulatory compliance. It’s a hands-on role that supports smooth project execution and cuts down on quality issues and communication breakdowns.

How does specification management support quality and sustainability goals?

Great specs lead to better products. With the right system, teams can manage fit consistency and measurement accuracy in one place. This leads to higher quality samples and fewer revisions, helping reduce waste and support broader sustainability goals.

Why do fashion brands need a centralized specification platform?

A single source of truth saves time and stress. Centralizing all the data gives teams quick access to everything they need, no more email threads or file-hunting. It also improves document sharing, supports better collaboration, and lowers risk. Fashion brands that want to deliver high-quality finished goods and scale their business need the ability to manage specs according to necessary standards, especially in fast-moving markets.

When should fashion brands invest in specification management software?

Fashion brands should invest when growing collections, expanding vendor networks, or stricter regulatory requirements make manual tracking harder to manage. As stakeholders get involved, strong document control and security become necessary to protect sensitive product data and maintain consistency. Investing early supports smoother collaboration, fewer errors, and long-term production success as the business scales.

Discover how Onbrand PLM can streamline your product development!

Discover how Onbrand PLM can streamline your product development!

© 2024 onbrandplm.com. All rights reserved.

© 2024 Onbrand. All rights reserved.