Jan 12, 2026

Ever wonder why some apparel products move smoothly from idea to production, while others slow down during sampling, sourcing, or approvals?

In the fashion industry, gaps between design, materials, and production often lead to delays, higher costs, and missed market opportunities.

Textile product development brings structure to these gaps by connecting textile design, raw materials, tech packs, and manufacturing processes into a clear, organized workflow.

It supports fashion product development by helping teams move from early concepts to well-made textile products that meet quality, performance, and market expectations, with decisions aligned across design, development, and production teams.

In this blog, we break down textile product development and how it fits into modern fashion workflows, covering the key stages, roles, and processes teams rely on.

TL;DR

Textile product development is the process fashion teams use to turn textile concepts into production-ready apparel and sewn products with clear specifications, timelines, and cost targets.

The work connects textile design, materials, tech packs, sampling, and manufacturing so teams can protect quality and avoid late changes.

A structured process supports customer expectations, cost control, and sustainability through early prototyping, documented approvals, and tracked updates.

Core stages include concept and research, design and technical planning, sourcing, sampling, pre-production, manufacturing review, and market launch.

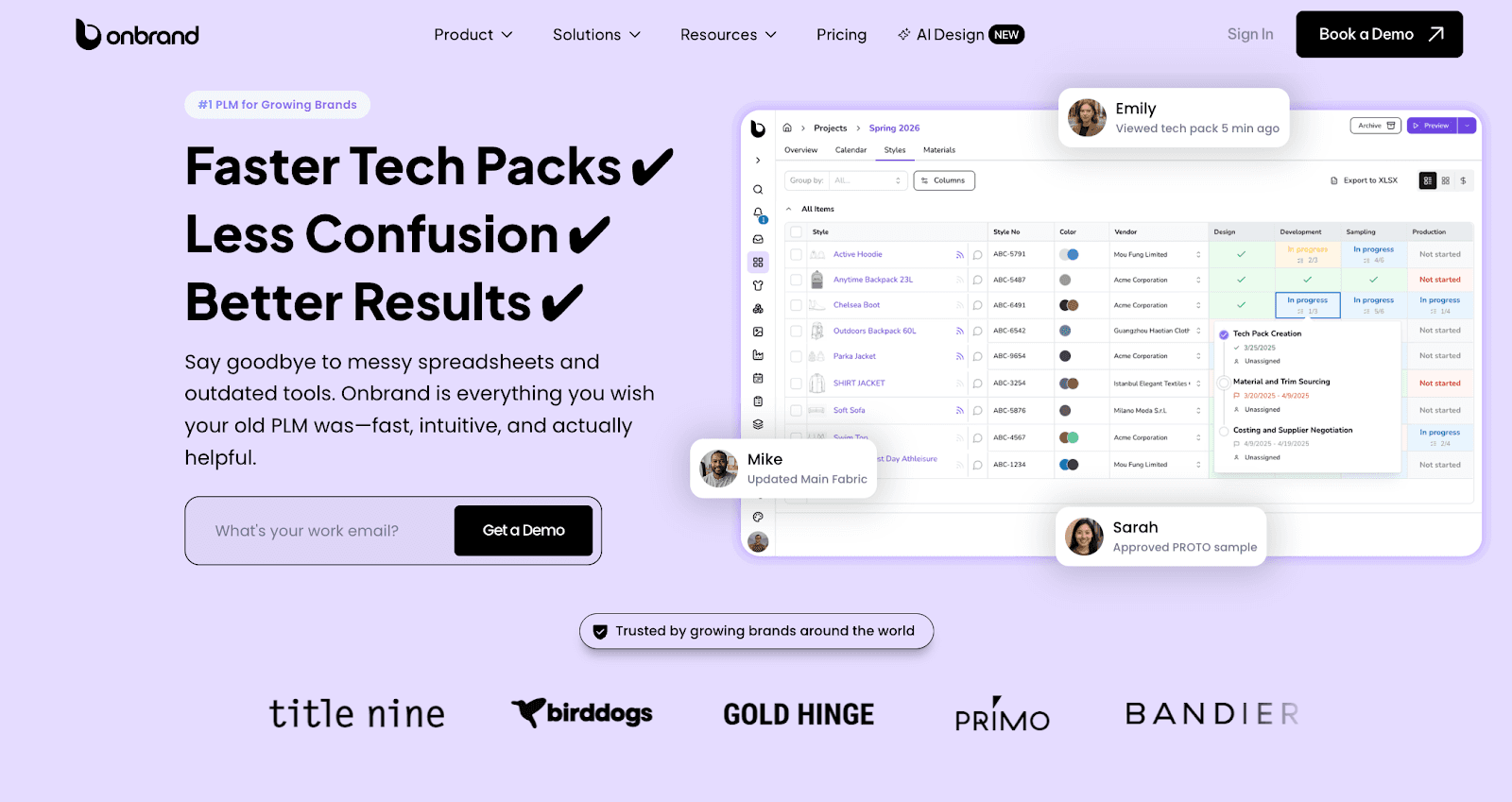

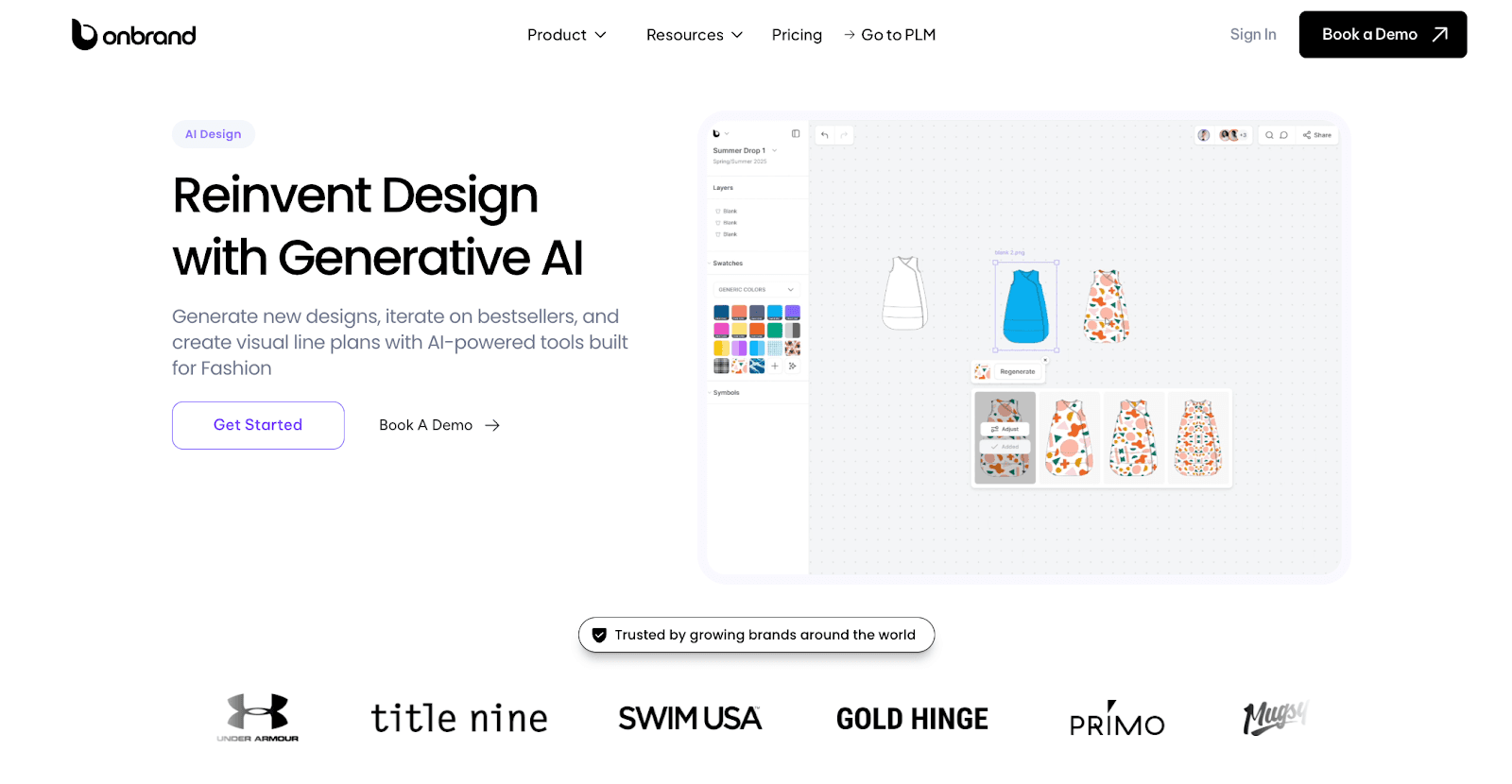

Tools like Onbrand support this workflow through a connected process across AI Design and PLM, linking early concepts with tech packs, samples, approvals, and vendor collaboration.

What Is Textile Product Development

Textile product development is the process fashion brands use to turn textile concepts and material ideas into finished apparel, accessories, and other sewn products.

It connects textile design, material selection, technical planning, and manufacturing, so products move from design to production with clear specifications, timelines, and cost targets.

Teams start with market research and consumer demand to define the target market. Designers and developers then select fabrics, raw materials such as cotton or new fibers, and test various techniques, including dyeing, digital printing, and finishing methods.

These decisions shape the tech pack, including measurements, specifications, and quality requirements.

Throughout development, teams work closely with textile manufacturers and suppliers across the textile industry to review samples, manage revisions, and confirm performance.

Textile product development balances cost, quality, and sustainability, while protecting intellectual property and addressing real production constraints within the fashion industry.

Why Textile Product Development Matters in the Fashion and Textile Industry

Textile product development gives fashion teams a clear path from idea to finished product. Without structure, quality suffers, costs increase, and timelines are compromised.

A defined process helps teams create and produce consistent new products that meet customer expectations and brand standards.

Decisions around textile product design, new materials, and finishing techniques are documented, reviewed, and approved before production begins.

This matters for daily work because product quality and delivery speed are equally important.

A strong development process supports teams by:

Keeping product management aligned with design and production decisions

Supporting early prototyping to test durability and fit before investment scales

Managing environmental impact through realistic, sustainable practices

Using digital technologies to track samples, changes, and approvals

Protecting margins through better cost control and fewer late changes

When teams follow a structured approach, they build reliable products, reduce risk, and deliver better outcomes for customers and the broader environment.

Stages of Textile Product Development

Textile product development follows a clear set of stages that guide teams from early ideas to finished new products. Each step builds on the last, helping teams manage quality, cost, and timelines with shared knowledge and clear ownership.

Concept and Research

This first course sets the direction for the season. Teams review trend inputs, customer needs, and brand goals to the unique opportunity for the line.

Early assortment planning and customer feedback guide decisions before work moves into detailed product development.

Design and Technical Planning

Designers translate ideas into sketches and construction details. This stage turns early concepts into build-ready direction.

Teams define measurements, confirm construction details, and prepare the first version of the tech pack, so development can move forward with fewer questions.

Onbrand AI Design supports this work by helping teams explore visuals, test variations, and align on sketches and details before specifications are locked.

Fabric and Trim Sourcing

Teams select textiles, trims, and finishes that meet cost and performance needs. Supplier coordination and testing support vendor relationship management and help teams plan for durable materials that match design intent and delivery timelines.

Pattern Making and Construction

Patterns turn designs into build-ready specifications. This step connects design with production reality and supports accurate sizing, construction logic, and specs for sewn products before samples move forward.

Sampling and Iteration

Samples are created, reviewed, and adjusted through structured sample management. Fit reviews, lab dips, and revisions help teams refine construction and materials before approvals. Clear feedback loops reduce delays later in development and production.

Pre-Production Planning

Pre-production confirms that everything is ready for manufacturing. Teams finalize materials, approve specs, review timelines, and check that every detail reflects the latest decisions before production begins.

Onbrand PLM helps teams manage live tech packs, approvals, and updates in one place so production starts from current information.

Manufacturing and Quality Review

Production moves forward with close oversight of textile manufacturing. Teams review material output, color consistency, and finishing techniques against approved specifications.

Regular quality checks help protect fabric performance, cost control, and delivery timelines before bulk cut and sew starts.

Market Launch and Line Delivery

Development hands off to merchandising and sales. Teams finalize delivery details, support launch timing, and prepare packaging and line materials. Clean handoffs help brands move confidently from build to market.

Roles Involved in Textile Product Development

Textile product development depends on clear ownership across teams. Each role supports a specific part of the workflow, from early ideas to approved production.

Designers - Lead creative direction by developing concepts, color stories, and construction ideas. Their ability to translate ideas into sketches and clear design elements sets the foundation.

Product developers - Manage the process of developing styles from concept through approval. They coordinate timelines, track changes, and balance cost, quality, and feasibility across teams.

Technical designers - Focus on fit, measurements, and construction accuracy. They maintain tech packs, review samples, and confirm specifications so products can move into production with fewer issues.

Sourcing teams - Work with vendors to select materials, trims, and finishes. Their work supports material choices while keeping lead times and cost targets realistic.

Production partners - Build samples and finished goods based on approved specs. Close coordination helps teams catch issues early and maintain consistency at scale.

When each role understands ownership and timing, teams maintain the ability to make innovative choices without losing control of cost or delivery.

Common Textile Decisions Made During Product Development

Throughout textile product development, teams make practical decisions that affect cost, quality, and timing.

Fabric selection often starts early, but final confirmation may wait until testing or sampling results are clear. Color approvals happen at set checkpoints, usually after lab dips or strike-offs. Sample iterations help teams adjust fit, construction, or material choices before final sign-off.

Cost and MOQ decisions sit alongside design intent. Teams balance innovation with production realities so new products remain viable for the target run.

These decisions stay manageable when teams document choices and keep updates visible.

How Teams Collaborate During Textile Product Development

Collaboration keeps textile product development aligned from early ideas through production.

Cross-team handoffs connect design, development, sourcing, and production at each stage. Designers pass concepts and materials to development. Developers share updates with sourcing. Production partners rely on approved specs and timelines.

Shared documentation supports this flow. Tech packs, sample notes, and approval records give teams a single reference for current decisions. Everyone works from the same inputs rather than separate files or emails.

Feedback loops play a key role in developing styles. Teams review samples, log comments, confirm changes, and move forward together.

A shared way of working protects quality and timelines. Clear communication reduces rework and keeps everyone aligned as styles move through the workflow.

Timeline Considerations in Textile Product Development

Timelines guide every phase of textile product development.

Sampling cycles determine how quickly teams can review and refine styles. Each round includes build time, review time, and decision windows. Approval timelines define when feedback must be shared so work can continue without delays.

Production readiness depends on confirmed materials, finalized specifications, and approved samples. Teams plan these milestones early to avoid rushing decisions later. Clear sequencing helps teams manage developing styles alongside other priorities.

Time planning supports realistic execution. When teams understand how long each step takes, they can test ideas without risking delivery dates.

Realistic timelines give teams the ability to move from concept to production with confidence. Clear expectations keep work moving forward and reduce last-minute changes.

Ways Teams Improve Textile Product Development Workflows

Clear structure and shared ownership help textile product development move forward without added friction. These best practices focus on day-to-day decisions teams make across fabrics, samples, and approvals.

Use a Central System to Track Textile Decisions

Textile development involves frequent changes to fabrics, trims, and construction details. When updates live across emails and spreadsheets, teams lose track of what is approved.

Using a fashion PLM like Onbrand PLM gives teams one place to manage tech packs, material updates, sample status, and approvals tied to each style. This helps designers, developers, sourcing teams, and vendors work from the same information throughout development.

Keep Tech Packs Clear and Consistent

Tech packs guide every stage of textile production. Each version should clearly reflect current measurements, materials, construction notes, and quality expectations.

Consistent formatting across styles reduces confusion during sampling and manufacturing. Clear documentation also helps suppliers follow instructions without assumptions or extra clarification.

Align Design and Development Before Materials Lock

Early design reviews help teams confirm that concepts match available fabrics, costs, and production timelines. These conversations work best before materials are finalized or samples are requested.

When designers, developers, and sourcing teams align early, textile choices stay realistic, and fewer revisions appear later in the process.

Make Sample Feedback Specific and Actionable

Sample reviews work best when feedback is direct and documented in one place. Notes should clearly explain fit issues, material changes, or construction adjustments.

Specific feedback shortens sample cycles and helps factories apply changes correctly on the next round.

Use Past Results to Guide New Textile Decisions

Previous sample outcomes, material performance, and sell-through results provide valuable context for new development work. Reviewing this information helps teams repeat what worked and adjust what did not.

Using real outcomes to guide textile choices supports better decisions across seasons without restarting from scratch.

Onbrand: Supporting Textile Product Development

Fashion teams handle two kinds of work at once: early creative direction and the detailed handoff into development.

Onbrand supports both with Onbrand AI Design for concept exploration and Onbrand PLM for tech packs, samples, approvals, and vendor coordination once decisions move into production work.

Managing Textile Product Development with Onbrand PLM

Once fabrics, trims, and specs start changing across rounds of samples, teams need one place to track what is approved and what is still open.

Onbrand PLM helps brands manage textile-related product data across product development by keeping materials, tech pack updates, sample status, and approvals tied to the same style record.

This keeps design, sourcing, and production aligned on timelines and the latest specs, so factories do not work from outdated files.

With Onbrand PLM in place, brands see 55% faster tech pack creation, shorter development timelines by up to 4 weeks, and data migration completed in roughly 10 days.

Key Features

Live web-based tech packs - Teams and vendors always see current measurements, materials, and construction notes.

Material and trim libraries - Keep fabrics, colors, artwork, and specifications organized in one place.

Sample management and approvals - Track sample rounds, feedback, and sign-offs without scattered threads.

Project management tools - Use stages, tasks, and approvals to match your team’s workflow.

Vendor collaboration hub - Keep comments and updates tied to the tech pack, not separate emails.

Early Design and Concept Exploration with Onbrand AI Design

Before textile choices lock, teams need fast visual alignment so development starts with clear direction.

Onbrand AI Design supports early-stage exploration by helping teams create and review concepts from prompts, sketches, or reference images, then iterate on variations before materials and specs move deeper into sampling.

This gives teams a cleaner handoff into development, since visuals, notes, and version history stay connected.

Brands using Onbrand AI Design report up to 10x faster design turnaround, 30 to 50% fewer physical samples, and more than 10 weeks saved each year.

Key Features

Concept generation from text, sketches, or photos - Create first pass visuals for review and direction setting.

Design exploration and variations - Test colorways, trims, and silhouette changes without starting over.

Photoreal renders and mockups - Support internal reviews, buyer presentations, and early factory context.

Visual collaboration - Comment directly on frames and track version history for clearer sign-off.

Connect to PLM - Send approved concepts and assets into Onbrand PLM to start development with clearer inputs.

When teams connect early visuals with development tracking, fewer decisions get lost between concept and production. You also get cleaner tech packs, clearer sample feedback, and faster approvals across design, sourcing, and vendors.

FAQs About Textile Product Development

What is a textile product developer's job description?

A textile product developer manages the process of turning textile concepts into production-ready products. They coordinate fabrics, trims, tech packs, samples, costs, and timelines while working closely with designers, sourcing teams, and manufacturers. In recent years, this role has expanded to include closer tracking of material performance and customer expectations.

What are the 5 major stages of product development?

The five major stages are concept and research, design and technical planning, sourcing, sampling and iteration, and pre-production planning. Each stage builds on the last, so businesses can control quality, cost, and delivery before manufacturing begins.

How does digital printing affect textile product development?

Digital printing allows teams to test colors, patterns, and artwork earlier in development without committing to large runs. During the introduction phase of a collection, this helps teams respond faster to consumer behavior while reducing sampling waste and supporting more flexible design decisions.