Jan 19, 2026

A tech pack typically costs anywhere from a few hundred to several thousand dollars, depending on the garment, level of detail, and production needs.

Simple styles with basic specs cost less, while complex designs, multiple sizes, and factory-ready documentation increase the total.

Because no two products follow the same path, tech pack pricing varies widely across the fashion industry.

Costs become easier to plan once you understand what goes into creating tech packs and how design details, revisions, and workflows affect time and effort.

Using the best tech pack software can help you control updates and avoid unnecessary rework.

In this guide, we break down typical tech pack cost ranges, pricing factors, and how to budget confidently for your business before moving into production.

TL;DR

Tech pack cost ranges from $100 to $1,200+ per style, depending on garment complexity, level of detail, revisions, and production readiness.

Costs increase with complexity, including multiple sizes, detailed construction notes, trims, graphics, and factory-ready specifications.

Key cost drivers include design complexity, number of styles, level of detail, revision rounds, and who creates the tech pack.

You can estimate your tech pack budget by following five steps: define style count, decide production readiness, map required components, plan for revisions, and choose the right workflow.

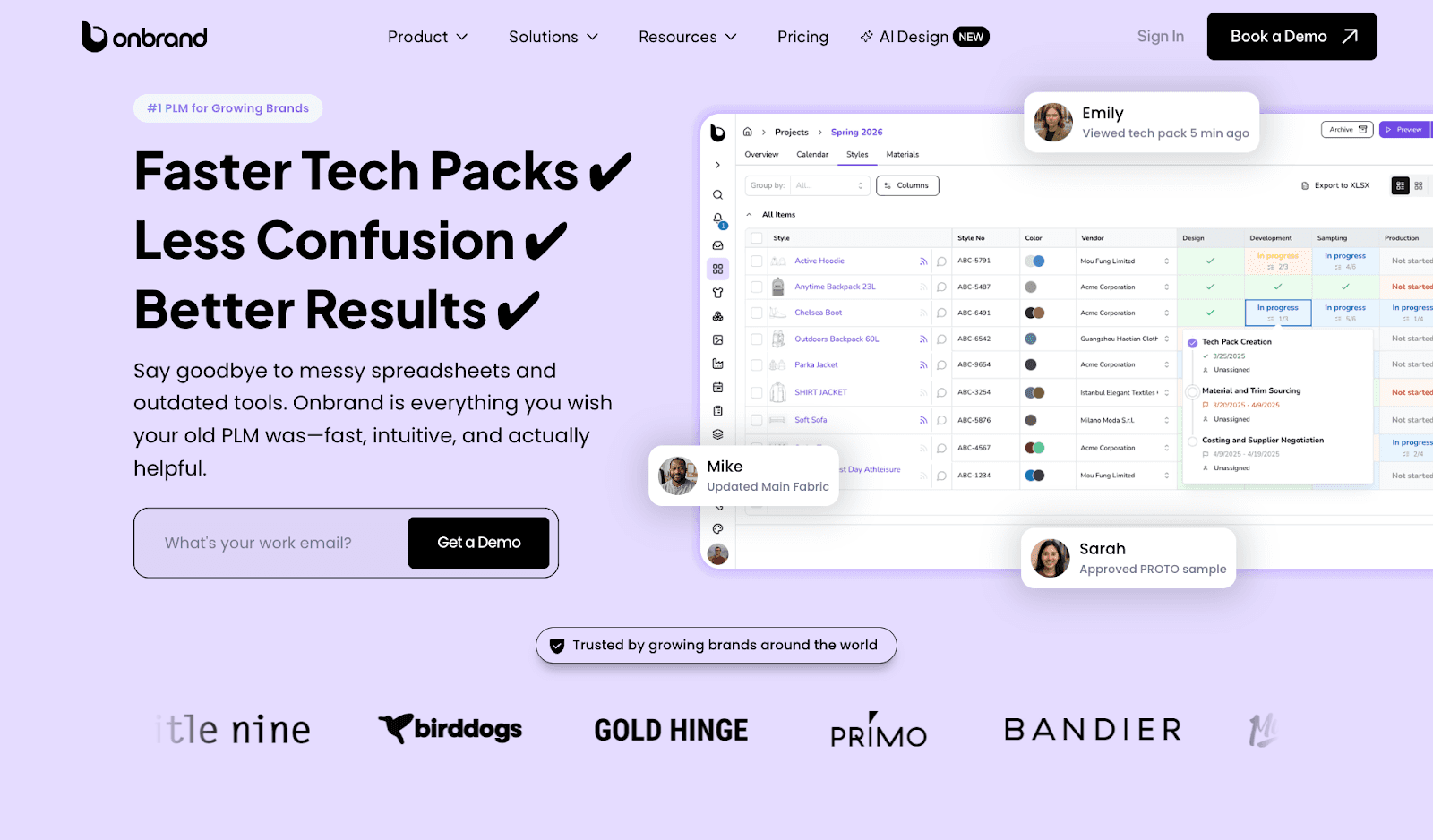

Centralized systems like Onbrand help keep tech pack costs predictable by keeping specs, samples, approvals, and visuals in one shared workspace.

What a Tech Pack Is in Apparel Production

A tech pack is the blueprint that guides garment production from concept to factory floor.

It brings together design details, materials, measurement points, construction details, and packaging details so a clothing manufacturer can produce a garment exactly as intended.

Tech packs also help you translate fashion design into clear, usable instructions for production.

Tech pack pricing depends on depth and accuracy. A solid tech pack with complete specs, clear visuals, and production-ready information takes more time to create, which affects tech pack pricing.

In contrast, a basic pack may work for early samples but often needs updates before bulk production, adding more cost later.

The difference comes down to purpose.

A concept-level pack supports early design, while a production-ready clothing brand tech pack supports factory handoff, approvals, and consistent quality at scale.

What Goes Into the Cost of a Tech Pack

Tech pack cost depends on how much work is required to turn a design into clear, factory-ready instructions. Understanding these factors helps you plan more accurately before production begins.

Design Complexity

Simple styles with minimal seams and trims take less time to document. Multi-component garments require more construction notes, measurements, and visuals.

The more detailed the garment construction, the longer it takes to prepare a tech pack that a factory can follow without question.

Number of Styles

A single-style tech pack costs less than creating packs for an entire collection. When styles share similar silhouettes or materials, you can reuse parts of existing templates.

That reuse lowers time spent per style and helps reduce overall cost across a collection.

Level of Detail Required

Concept-level packs support early samples and design review. Production-ready packs include grading, tolerances, and detailed specifications for factory use.

More detail means more documentation work, which increases cost but reduces confusion later in production.

Revisions and Updates

Each revision adds time. Changes after samples, fittings, or vendor feedback often require updates across measurements, specs, and visuals.

Clear version control helps explain changes, avoid duplicate work, and keep costs from climbing as the project moves forward.

Who Creates the Tech Pack

Freelancers charge per style or project. In-house teams spend internal time instead of direct fees.

Software-based workflows help you organize updates, specs, and approvals in one place, which reduces repeated work and keeps costs more predictable.

Typical Tech Pack Cost Ranges

In most cases, tech pack services fall within a predictable range once you look at the scope and complexity.

For fashion brands today, tech pack costs usually start around $100 to $500 per design for simple garments with limited details and few revisions.

As styles become more complex, pricing increases.

Mid-range tech packs often cost $300 to $1,000 per style, especially when they include multiple sizes, detailed construction notes, trims, and clear factory instructions.

For highly detailed or production-ready packs, costs can reach $1,200 or more per style, particularly when a project involves a bunch of revisions, complex materials, or multiple factories.

These packs take more time and space to document clearly.

Across the fashion world, this range is what most brands should expect when budgeting for tech packs that factories can actually use.

Brands arrive at these numbers in different ways, whether paying per style, budgeting per collection, or accounting for internal development time, so planning around a realistic range helps avoid surprises once revisions and production feedback begin.

Step-by-Step: Estimating Your Tech Pack Budget

Estimating a tech pack budget works best when you break the work into clear decisions.

Instead of guessing a number, look at how many styles you’re developing, how ready they need to be, and how you plan to manage updates as production moves forward.

Step 1: Define Your Style Count

Start by listing how many styles need tech packs. A small capsule collection of three to five styles costs less per style than a large launch with many unique silhouettes.

Similar styles often share a tech pack template, which helps reduce setup time and keeps costs more predictable.

Step 2: Decide the Level of Production Readiness

Next, decide whether you’re validating concepts or preparing for manufacturing. Concept packs support early samples and fashion design review.

Production-ready packs support bulk orders and factory handoff. The closer you are to production, the more detail is required, which affects the budget.

Step 3: Map Required Components

List what each pack needs. This often includes a flat sketch, measurements, a spec sheet, materials, and construction notes.

Some styles also require trims, fabric details, accessories, or graphics. More components mean more documentation time, which increases cost.

Step 4: Factor in Revisions

Most tech packs go through multiple updates after samples and fit reviews. Plan for at least two to three revision rounds.

Early alignment between fashion designers and production partners helps avoid a hard time later and keeps revisions from adding unnecessary cost.

Step 5: Choose Your Workflow

Finally, decide how you’ll build tech packs. Manual documents may work for small projects, but take more time to update.

Software-based systems help organize files, approvals, and specs in one place, which protects your budget as your brand scales.

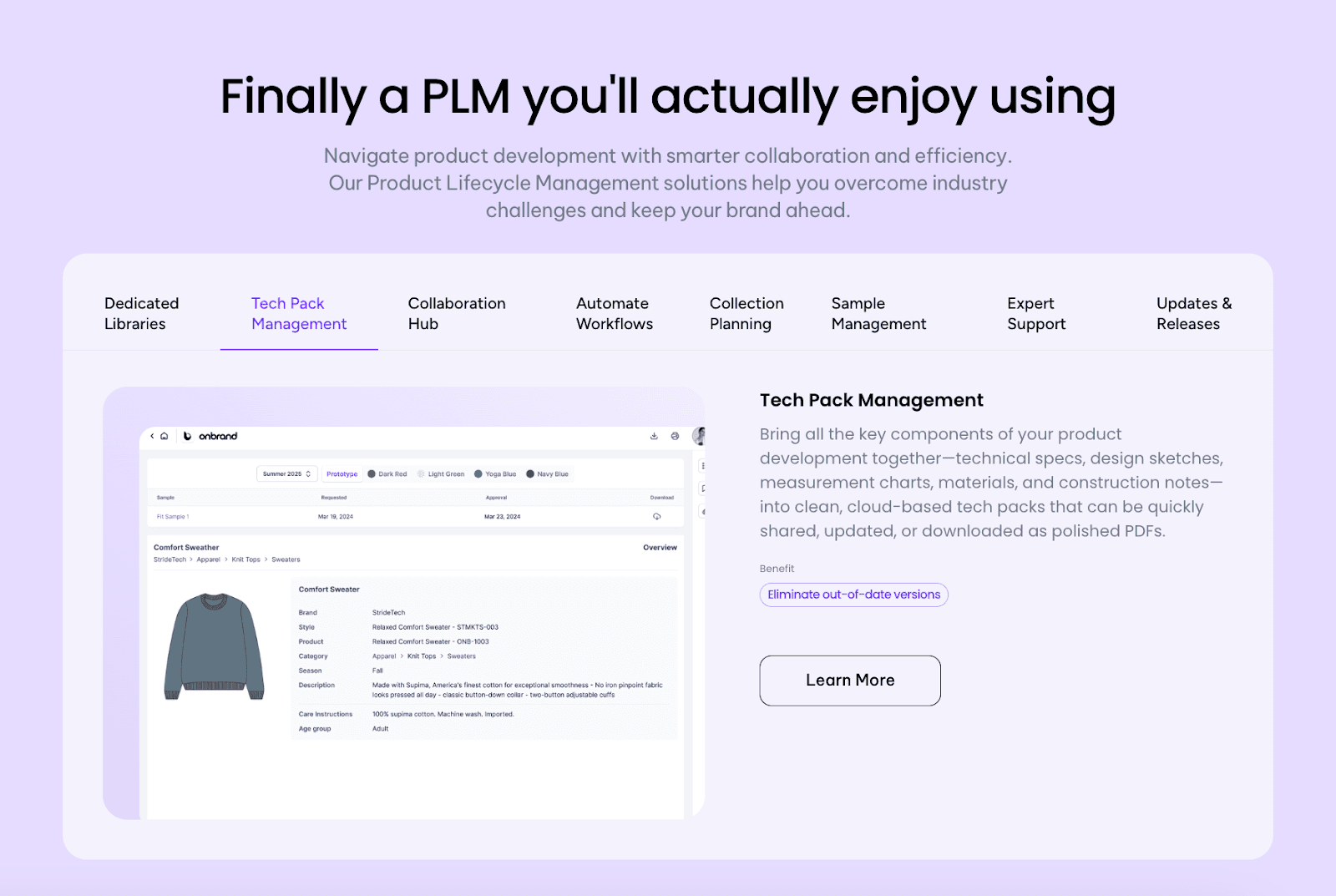

Onbrand: The Shared Workspace for Cost-Ready Tech Packs

When tech packs live in files and inbox threads, costs add up through repeated edits, missed updates, and extra sample rounds.

Onbrand helps you keep specs, approvals, and vendor feedback in one shared place, so you spend less time rebuilding the same work across versions.

Onbrand PLM

Onbrand PLM keeps tech packs connected to styles, samples, and timelines in one workspace. Updates stay visible as styles move forward, which helps avoid paying for the same changes more than once.

Where it helps reduce costs:

Live tech packs - Everyone works from the current record instead of downloaded files.

Version control - Changes are tracked, which limits duplicate revisions after fittings.

Linked samples and approvals - Feedback stays attached to the style, not scattered across messages.

Vendor access - Factories see the same specs and comments you see, which reduces back-and-forth.

Reusable libraries - Materials, colors, and artwork stay organized for future styles.

Brands using Onbrand report outcomes such as 55% faster tech pack creation, a 4-week reduction in development time, and 10-day onboarding and data migration in many cases.

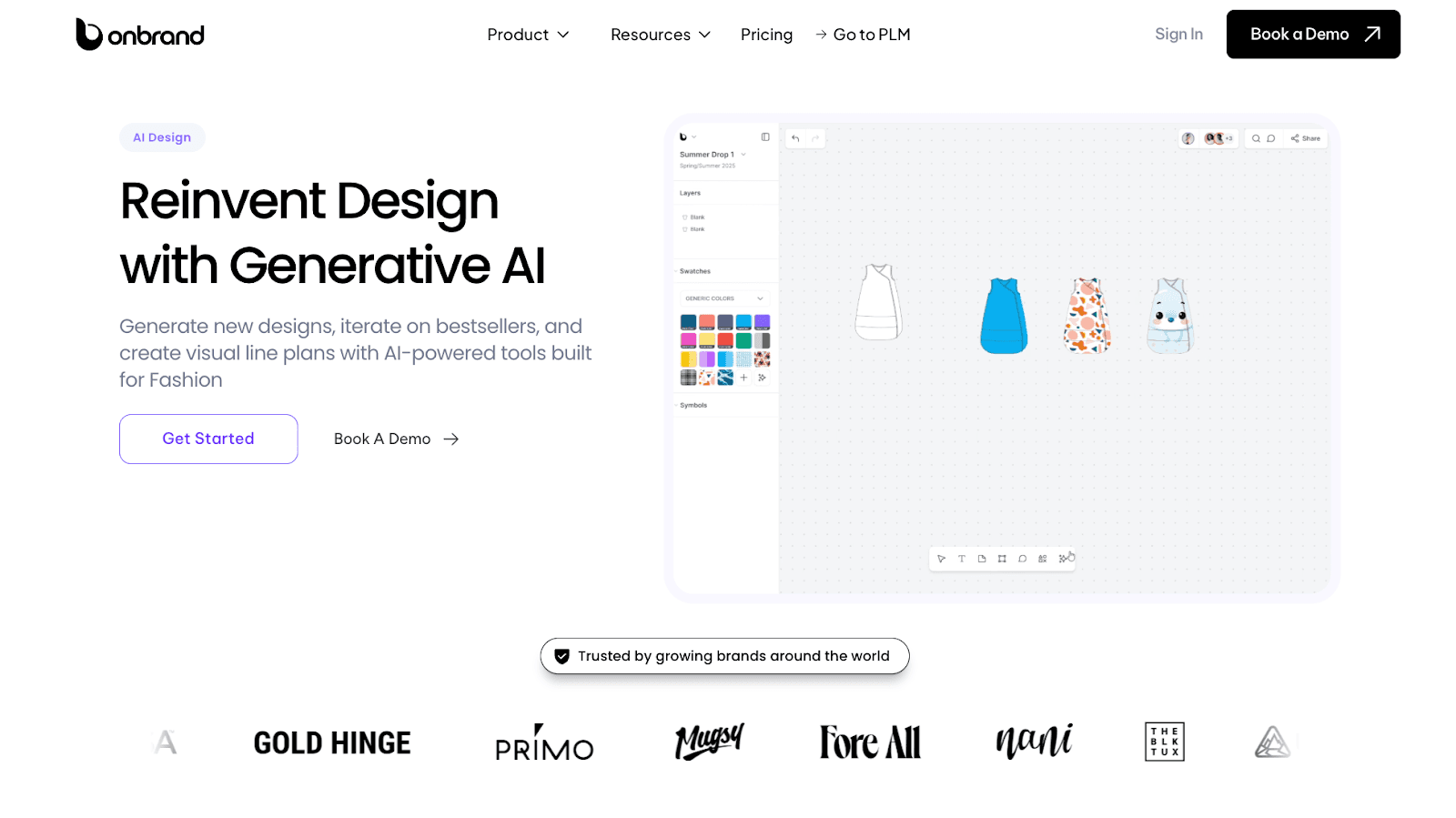

Onbrand AI Design

Onbrand AI Design helps you align on visuals earlier, before a tech pack reaches production detail. When direction is clear up front, teams spend less time revising specs, samples, and construction notes later in the process.

Features that support cost control:

Concept generation - Create design options from text, sketches, or reference images.

Design exploration - Test colorways, trims, and variations without starting over.

Visual collaboration - Leave feedback directly on mockups so changes stay clear.

PLM connection - Send approved visuals into PLM for faster handoff.

If you want to explore AI Design without committing a large budget, the pricing starts at $49 per user per month for the Design Starter plan. This includes up to 2,400 image generations per year, unlimited high-resolution exports, and full design privacy.

For teams that need collaboration and editing tools, Design Pro at $99 per user per month adds multi-user access, unlimited generations, vector exports, image editing, and enhanced support.

Brands that choose annual billing receive a 25% savings, and enterprise plans are available for larger teams or custom setups.

When Spending More on a Tech Pack Makes Sense

Spending more money on a tech pack makes sense when mistakes would be costly to fix later.

If you are preparing for bulk production, working with a new factory, or launching a complex style, clearer documentation adds real value.

This often applies when you design tech packs with detailed construction notes, measurements, and supporting elements like embroidery placement, a hang tag, or care label instructions. Extra detail helps factories follow intent without guesswork.

Higher investment also makes sense when multiple people review the same style. Without clear ownership and shared visibility, feedback can spread across files and messages, which leads to confusion.

The benefits show up as fewer remakes, faster approvals, and smoother factory communication. In those cases, a stronger tech pack uses more resources up front but saves time and rework as the product moves forward.

Keeping Tech Pack Costs Predictable as You Scale With Onbrand!

Tech pack cost depends on clarity, detail, and how well your process supports change as styles move forward.

Simple packs may work early on, but production-ready documentation often saves time, money, and rework once samples, vendors, and approvals enter the picture.

For growing fashion brands, cost control is not just about paying less up front. It comes from keeping specs accurate, updates visible, and everyone aligned across design and production.

That is where a shared fashion PLM system makes a real difference.

Onbrand brings tech packs, samples, timelines, and visuals into one place, so you spend less time fixing issues and more time moving products forward.

From live tech packs in PLM to early visual alignment with AI Design, Onbrand helps brands manage costs without cutting corners.

FAQs About How Much Does a Tech Pack Cost

How much does Techpacker cost per month?

Based on publicly available pricing, Techpacker’s Techpack Builder plan costs $70 per user per month on a monthly billing. Higher-tier plans, including PLM Professional and PLM Premium, are available only on annual billing, priced at approximately $95 to $125 per user per month when paid yearly. All plans are priced per user rather than per style.

What does a tech pack include?

A tech pack typically includes a flat sketch, measurements, materials, construction notes, and packaging details for production. Many brands build the sketches in Adobe Illustrator, while Onbrand connects early design visuals with live tech packs in PLM so specs, revisions, and approvals stay in one place.

How does tech pack pricing differ between manual creation and software tools?

Tech pack pricing differs based on how packs are created. Manual creation through freelancers or agencies is usually priced per style or project and can vary by client needs and garment complexity. Software tools charge a recurring monthly fee per user, which is often more predictable for brands managing multiple styles, revisions, and ongoing sample updates.