Nov 26, 2025

Fashion and retail teams deal with short deadlines, global suppliers, and constant product changes. Each collection brings new fabrics, new costs, and new delivery targets.

When information sits in different files and email chains, updates don’t reach the right people in time, and decisions take longer than they should.

Product lifecycle management (PLM) collaboration brings everyone into one shared workspace.

Designers, merchants, sourcing teams, and vendors work from the same product data, comment directly on updates, and review approvals without digging through old threads.

Work moves forward with fewer roadblocks, and teams spend less time fixing avoidable mistakes.

In this article, you’ll learn how PLM collaboration helps fashion teams stay connected and keep work moving with less effort.

What Is PLM Collaboration?

PLM collaboration is a shared approach to working within a PLM system that keeps design, merchandising, sourcing, production, and vendors aligned.

Each team works within a centralized system, eliminating the need to juggle separate files or long message threads. Your product data stays in one place, which helps everyone move with clarity during product development.

Comments, tasks, and approvals are listed alongside styles, materials, costs, and timelines. Your teams see the full context without searching across different systems or requesting updates.

That structure creates a collaborative environment where project managers, vendors, and contract manufacturers stay on the same page at every stage of the product lifecycle.

Strong PLM collaboration limits repeat work and reduces errors because each update is based on the same source of truth. Your teams gain a clearer view of change requests, supplier relationships, and potential risks inside one organized flow.

That level of alignment helps maintain product quality and supports informed decisions as you respond to market demands.

Key Collaboration Workflows Inside PLM

Teams across the fashion industry today deal with fast shifts in styles, costs, and timelines. Strong PLM systems offer structures that help your project teams move through each stage of fashion product development with less effort.

The workflows below show how different departments can effectively collaborate inside a single source of truth that manages product data with real-time visibility and fewer gaps between steps.

Design And Product Development

Designers, product developers, and technical teams share sketches, early concepts, and updated tech packs in one place. Your team sees live changes to style details, fit notes, and BOMs without waiting for separate downloads.

That level of design collaboration supports clear data sharing and helps maintain data integrity across your PLM data. You also have fewer manual interventions during the production process because everyone works inside a collaborative environment.

Merchandising, Planning, And Line Building

Merchants and planners review assortments, track counts, and adjust options within a shared view. Each product record connects margin details, timing updates, and line changes.

Different departments gain faster clarity because each update supports communication and collaboration without added document management or scattered files.

Sourcing, Costing, And Production

Sourcing teams and vendors work together on costs, MOQs, lead times, and material choices. A clear view of supplier information supports better supplier performance across the supply chain collaboration flow.

Your team can review cost negotiations, explore alternate fabrics, or shift delivery dates while keeping the production process on track.

Strong supplier collaboration supports quality assurance goals and keeps teams aligned with the needs of modern manufacturing without adding extra tools.

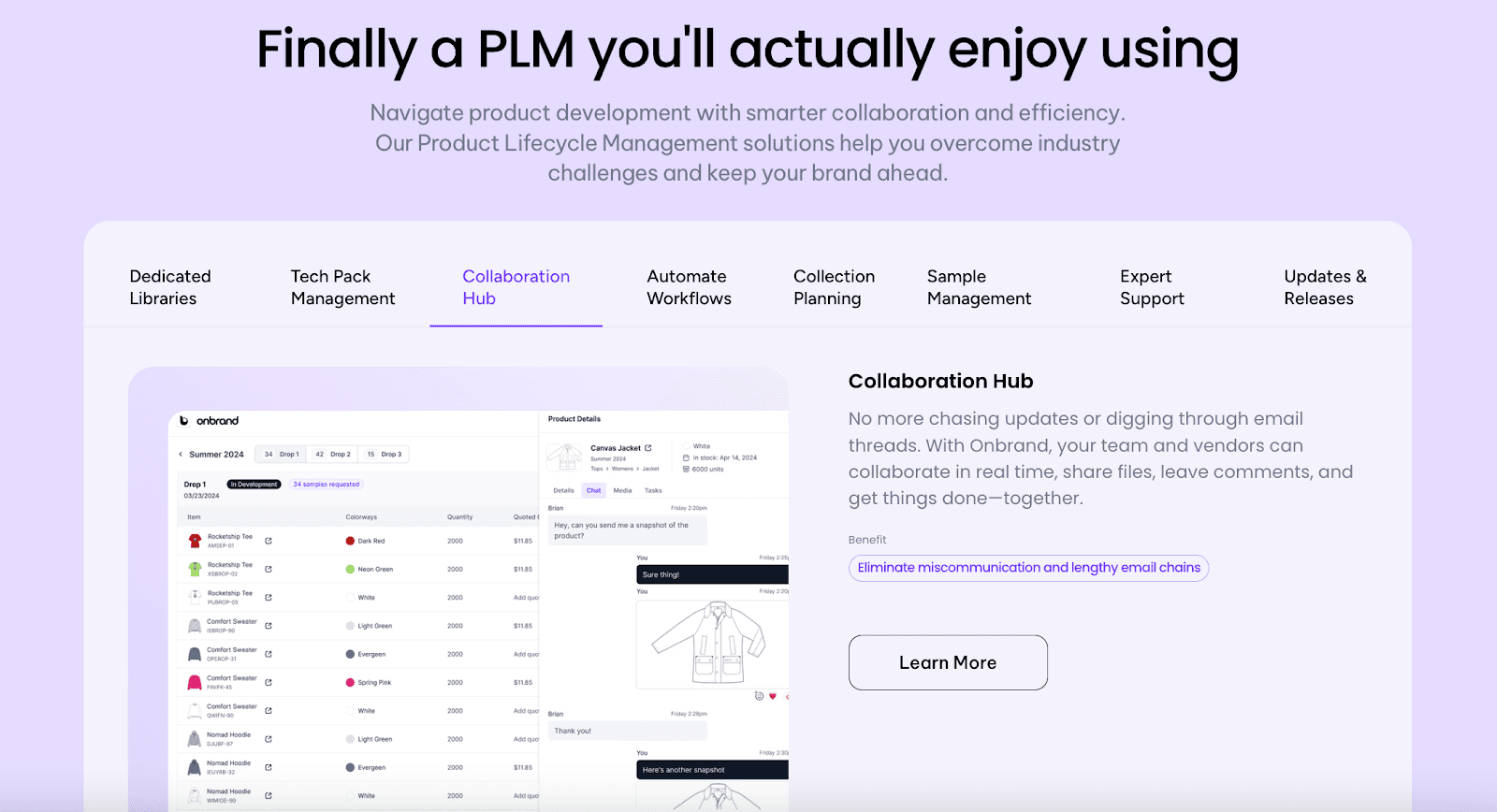

Vendor Communication And Approvals

Vendors access organized tech packs, size runs, sketches, and revision history. Fit notes, lab dips, and sample approvals move faster because everything sits inside the same collaboration platform.

Each stakeholder reviews up-to-date information and handles change management inside a shared workspace, a crucial role in keeping production on track. Your team avoids potential risks tied to scattered updates or outdated files.

Sustainability, Compliance, And Quality

Material data, certifications, and compliance documents sit next to product details. Your teams track regulatory compliance, safety requirements, and quality standards without leaving the PLM solution.

This structure supports continuous improvement efforts, improves product quality, and helps teams meet market demands with clear, efficient collaboration.

The workflow creates a competitive advantage because quality checks, apparel inspection notes, and specification management stay connected to each style.

Everyday Use Cases For PLM Collaboration Solutions

PLM collaboration supports the day-to-day work of cross-functional teams in the fashion industry. The use cases below show how teams keep work moving with real-time collaboration and clear visibility across each stage of product development.

New season kickoffs - Teams share concept boards, product briefs, mood board ideas, and early line plans inside one workspace.

Fit and sample rounds - Fit notes, photos, pattern updates, and approvals stay in one place. Vendors gain a clear view of expectations, which supports improved collaboration and stronger specification management.

Late design or material changes - A single update reaches everyone without extra messages. Your team avoids scattered files and keeps work aligned with the style, fabric, and trim details captured in your PLM data.

Price and margin updates - Merchants, finance, and sourcing teams review shared cost and margin data in one structured view. That structure supports collaborative problem solving without extra tasks.

Market pack and region changes - Regional teams flag needs or adjustments directly in product records. Each change connects to the related style without slowing production work.

Best Practices For Strong PLM Collaboration

Strong PLM collaboration grows out of simple habits that help your team stay organized and confident in every update. The practices below guide fashion teams through daily work without extra steps.

Set clear ownership - Assign owners for style details, timelines, materials, and cost updates. Each product record stays accurate when every stage connects to a responsible team member.

Keep comments close to the work - Use field-level comments and task notes inside your PLM software instead of side chats. Your team gains one traceable place to review changes.

Agree on naming and structure - Create simple rules for style codes, seasons, collections, and folder setups. That structure helps teams read PLM data without extra explanations.

Use tasks and deadlines inside PLM - Assign actions for samples, approvals, revisions, and fit rounds. Automated workflows keep project teams aligned and reduce the chance of missed steps.

Train vendors as true partners - Show vendors how to open, update, and comment inside the shared workspace. Clear access supports accurate work and fewer repeated questions.

Review collaboration habits regularly - Check where delays appear and remove barriers in small steps. That steady refinement supports continuous improvement across different departments.

Onbrand: The PLM Software Built for Faster Collaboration in Fashion

Fashion teams lose time when information lives in different places. Searching for updates, chasing the latest file, and waiting for confirmation slow down development work.

A modern workspace removes those roadblocks by keeping product details, tasks, and communication in one place where everyone stays aligned.

Onbrand supports that level of clarity through two connected offerings. Onbrand PLM serves as the core platform for product development, and Onbrand AI Design gives teams a creative space to explore ideas early before handing them off for development.

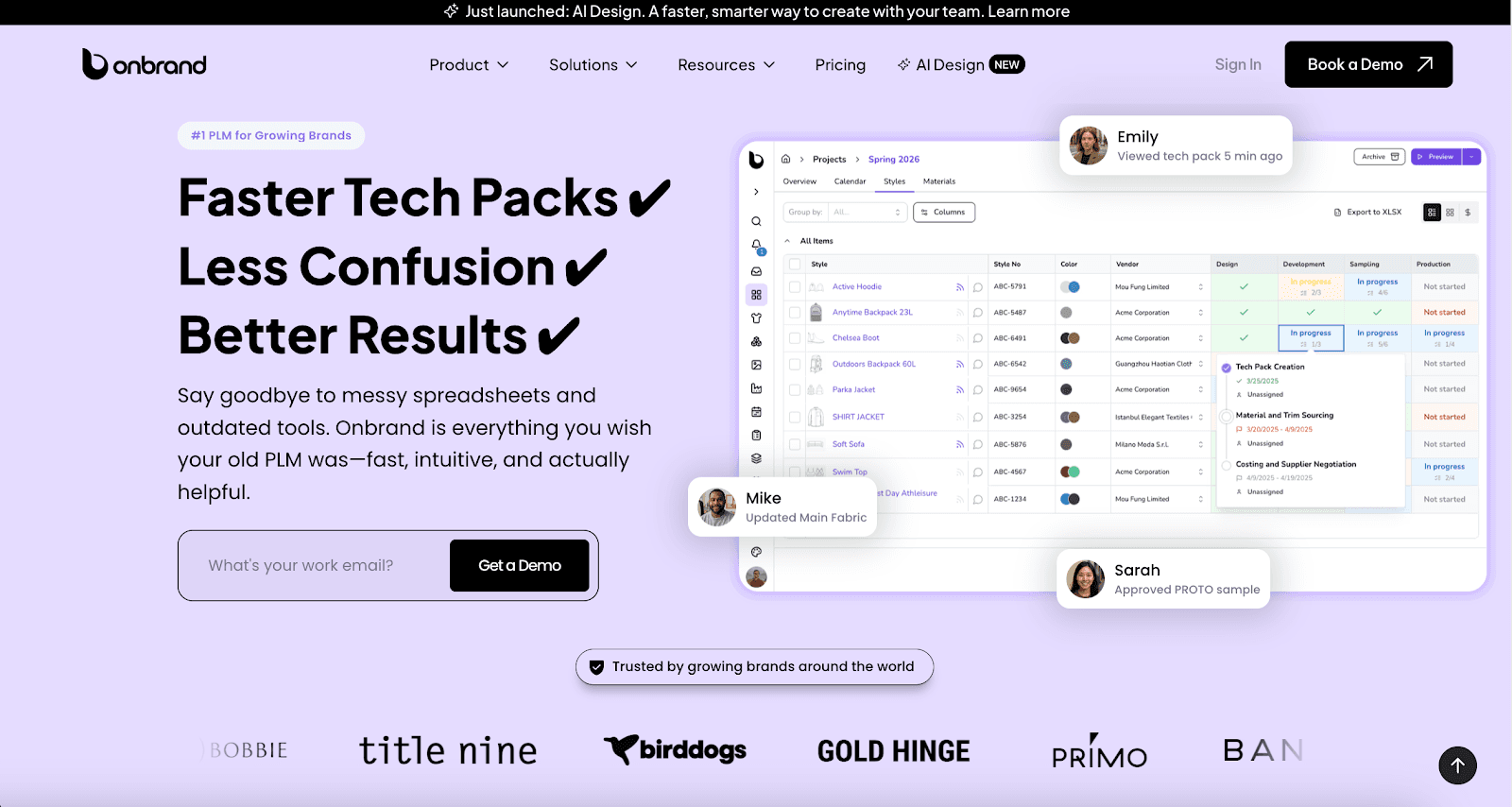

Onbrand PLM – Live Product Data For Every Team

Onbrand PLM gives fashion teams one workspace for styles, materials, costs, timelines, and tasks. Each update sits inside a live environment supported by strong PLM capabilities that replace outdated PDFs and spreadsheets.

Teams gain a fast, intuitive system that supports clear development work without long configuration cycles or consulting-heavy setups found in legacy tools.

Key ways Onbrand PLM strengthens collaboration:

Live tech packs update in real time, which keeps design, merchandising, and sourcing aligned without repeated files.

In-context comments and approvals help teams respond inside the product record, which cuts down on email threads and scattered feedback.

Simple vendor access allows factories to review samples, costs, and fit details inside the same record your team uses.

Project views show status across seasons, categories, and collections, giving teams clarity during each stage of the workflow.

Dedicated libraries organize materials, colors, artworks, and specs in one source of truth, which supports clean and consistent work.

Onbrand PLM stands out because it gives teams clarity without heavy consulting fees or rigid templates. The platform adapts to your workflow, removes messy spreadsheets, and cuts tech pack creation time by up to 50%.

Most teams launch within 2 to 4 weeks, with successful migrations completed in days rather than months.

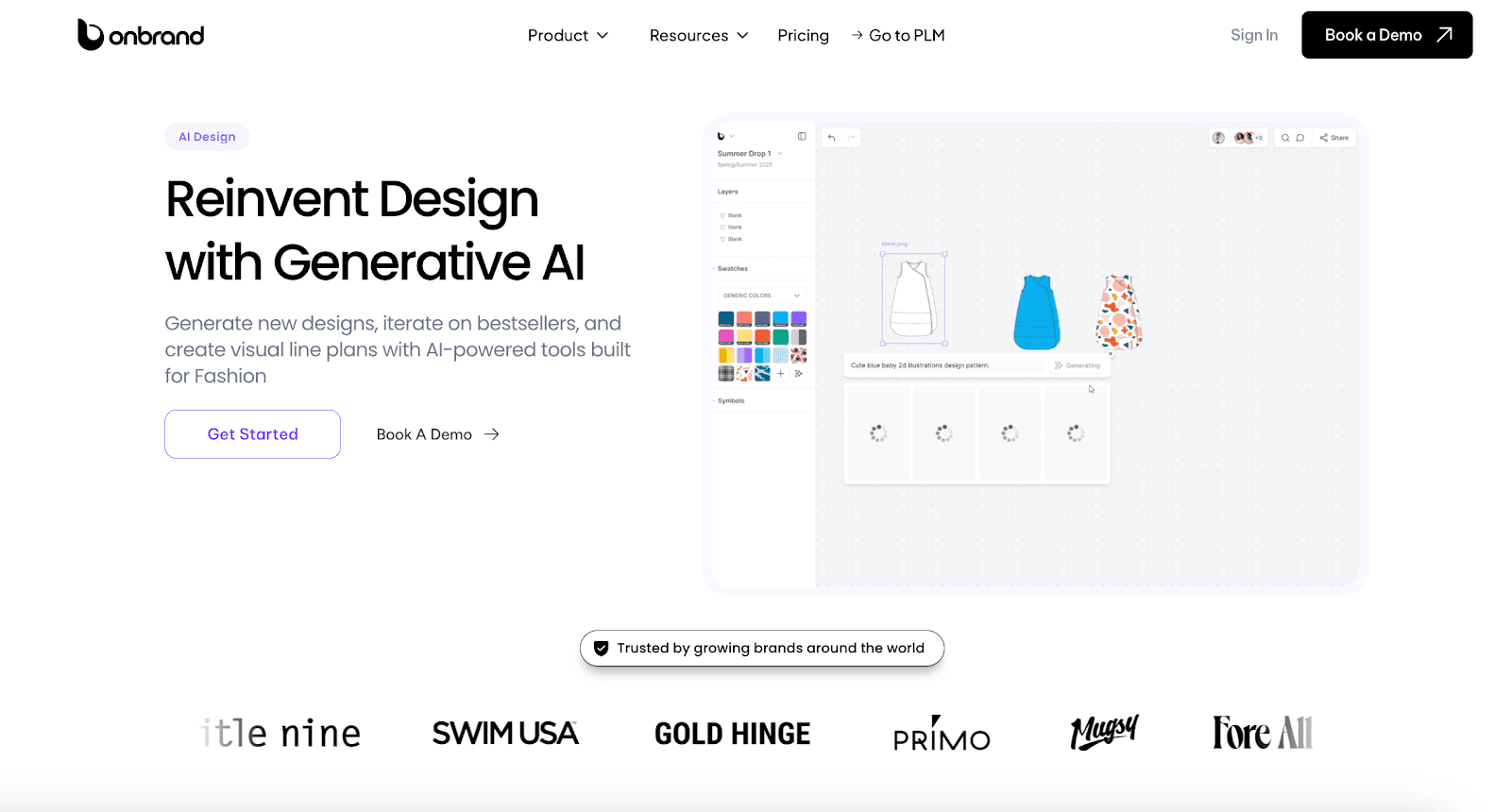

Onbrand AI Design – Collaborative Space For Early Creative Work

Onbrand AI Design creates a shared creative room where designers explore visual ideas and category managers shape early direction.

Teams build concept boards, test color ideas, compare garment variations, and refine inspiration inside one workspace without switching between tools.

Designers turn written ideas into visual options, organize inspiration, and adjust details before handing selected concepts into Onbrand PLM. Early clarity helps product development start with a stronger direction and fewer revisions.

AI Design and PLM work together to keep teams aligned from the first sketch through production. Creative work becomes easier to review, share, and bring into development, without scattered files or version confusion.

Help Your Team Stay Aligned With Onbrand’s Connected Workspace!

Effective collaboration shapes how smoothly each season comes together.

When teams rely on scattered tools, information gaps slow decisions and create extra work.

A shared workspace turns that complexity into clarity, which gives designers, developers, merchants, sourcing teams, and vendors one reliable place to move through each step with confidence.

Onbrand PLM brings that structure to everyday product development. Your teams get live tech packs, organized libraries, vendor access, and project views that keep work moving without confusion or repeat tasks.

And with Onbrand AI Design, early creative work moves smoothly into development with visuals and direction already in place.

If you’re ready to replace outdated tools with a platform built for modern fashion teams, Onbrand PLM gives you a clearer, faster way to build and scale collections.

Book a demo today and see how Onbrand can support your team’s workflow.

FAQs About PLM Collaboration

What does PLM stand for?

PLM stands for Product Lifecycle Management. It is a centralized approach to managing styles, materials, samples, approvals, and all product data in one workspace. Teams use PLM to improve visibility, strengthen product data management, and reduce errors across development.

What are the 5 phases of PLM?

The five common phases of PLM include concept, design, development, production, and launch. These phases help teams move ideas into finished products while keeping updates, tech packs, supplier input, and CAD systems connected inside one structured process.

What is PLM integration?

PLM integration connects your PLM platform with other tools your team already uses. This can include ERP platforms, CAD software, design tools, vendor portals, or analytics systems. Integrated workflows support faster updates, reduce manual work, and often reduce costs in production.

What is an example of PLM?

An example of PLM is a cloud platform that stores tech packs, manages changes, tracks samples, and keeps designers, merchants, sourcing teams, and vendors aligned. Many fashion teams choose solutions built for digital transformation, using new technologies and machine learning to stay organized. These systems give senior director–level leaders a clear view of collaboration and production progress.