Dec 3, 2025

Fashion teams today are working in one of the most exciting yet demanding times. Trends move faster, sustainability goals are stricter, and customers expect more than ever before.

Each collection must strike a balance between creativity and speed, and that’s not easy when every step, from design to delivery, depends on precision.

As fashion technology changes, many fashion brands are rethinking their approach to planning, creating, and delivering collections across both physical and digital channels.

From luxury houses to fast fashion labels, growing consumer demand and online sales have made speed, visibility, and innovation central to success.

Here’s how digital transformation is guiding the fashion industry’s shift toward faster, smarter, and more sustainable ways of working.

TL;DR

Digital transformation in fashion replaces manual, disconnected workflows with connected digital systems that streamline design, sourcing, production, and retail.

It helps brands move faster, reduce waste, and make decisions using real-time data instead of guesswork.

Digital tools improve product development by linking sketches, specs, materials, and feedback in one organized workflow.

Virtual samples, accurate forecasting, and traceable data support sustainability goals and reduce unnecessary production.

Onbrand PLM supports this shift by combining PLM and AI design tools to help fashion teams work faster, align more easily, and move from concept to production with clarity.

What Digital Transformation Means for Fashion

Digital transformation in fashion means moving away from scattered files and manual updates toward connected digital tools that keep every part of the business aligned and integrated.

It helps fashion brands link creative ideas with real production details, turning once-separate tasks into one continuous workflow.

Across design, sourcing, and merchandising, teams now use digital technologies to simplify communication and decision-making.

Fashion executives gain a clearer view of the entire value chain, while buying and merchandising teams work with real-time data that reflects customer preferences and sales trends.

For many fashion companies, this shift marks a true digital revolution. Tools powered by artificial intelligence, predictive analytics, and machine learning techniques guide everything from trend planning to material choices.

Digital platforms also connect creative and operational teams, replacing outdated physical prototypes with virtual samples that reduce waste and shorten development time.

In short, digital transformation in fashion helps teams stay ahead of demand, adapt faster to market changes, and build a more connected way of working that benefits everyone.

Benefits of Digital Transformation for Fashion Brands

Digital transformation isn’t just changing how fashion teams work, but what’s possible. The right digital tools help brands cut waste, move faster, and create better products without losing their creative edge.

Smarter Product Development

Fashion moves fast. What worked last season might not work now. Teams need clear systems that keep up with constant change.

Digital tools connect sketches, specs, and feedback in one place, making it easier to refine products without starting over.

When everything from materials to samples runs through connected data, there’s less room for error. Ideas move quickly from concept to approval.

It’s no longer about chasing updates across files or waiting for sign-offs. It’s about working in sync across the entire supply chain. For many fashion businesses, that clarity means better use of time and fewer delays across departments.

Sustainability and Waste Reduction

Waste has always haunted the fashion industry. Overproduction, leftover raw materials, and excess inventory erode margins and harm the planet.

Digital fashion processes change that. Virtual samples and accurate forecasting help teams make smarter calls before a single fabric is cut.

Digital solutions keep teams close to real-life data, showing exactly what customers want and how much to produce. These tools also make it easier to track every component across manufacturing processes and align with sustainability requirements.

When digital systems replace guesswork, waste turns into opportunity. Less fabric is lost, and more focus is on what sells.

Greater Transparency and Traceability

Fashion’s supply chains stretch across continents. Keeping visibility over every stage used to be impossible. Now, connected digital systems show how products move through design, sourcing, and production in real time.

Blockchain technology adds another layer of trust, verifying where materials come from and who handles them. That kind of clarity matters for customer interaction and loyalty. People want to know the story behind what they buy.

Digital innovation helps brands manage accountability across complex networks, from luxury groups to fast fashion labels. The result is cleaner data, stronger partnerships, and a more reliable reputation.

Inclusive and Innovative Design

Design is where creativity meets data. Digital fashion tools make it easier for teams to experiment, test ideas, and represent more people. Virtual and augmented reality technologies turn sketches into realistic previews that show how garments look on different bodies.

Many fashion brands now use digital fashion design software to open the process to wider collaboration. Designers share 3D assets, update specs, and build visual line plans together without slowing down.

Digital transformation provides the fashion design process with greater flexibility. Ideas move faster, feedback happens in real time, and innovation becomes part of everyday work.

Faster, Data-Driven Decisions

In the past, decisions relied on instinct. Today, data analytics shape everything, including what to produce, where to sell, and how to price it. Digital tools collect information across online sales, physical stores, and social media, revealing what customers actually respond to.

When fashion brands combine real-time insights with trend forecasting, they see patterns early. They can react to consumer demands before competitors do.

This balance of creative intuition and measurable insight gives teams a clear competitive advantage in a crowded market.

Embracing technology doesn’t replace creativity; it sharpens it. The more connected the system, the faster brands can adapt, create products customers love, and build stronger engagement that lasts.

Examples of Digital Transformation in Fashion

Digital transformation looks different across every part of the fashion industry. Some changes happen behind the scenes through smarter workflows, while others reshape how customers experience fashion in stores or online.

Here’s how fashion brands are adopting digital tools to stay connected, creative, and customer-focused.

1. Product Lifecycle Management (PLM)

Fashion brands handle countless details across every collection, including materials, fits, costs, and timelines. PLM systems bring all those details together, keeping teams aligned across design, sourcing, and merchandising.

Modern PLM software replaces scattered spreadsheets with connected data that supports faster approvals and fewer errors. It keeps every stage of production visible, which helps teams make quick adjustments when needed.

For many companies, PLM has become the foundation for efficient core business processes. It helps fashion teams modernize existing processes with new systems that support collaboration across the entire product lifecycle.

2. AI-Powered Fashion Design

Design once started with a sketch and a mood board.

Now, AI tools help creative teams visualize ideas more quickly, generate color options, and plan collections that better reflect customer preferences. These digital tools speed up decision-making without limiting imagination.

Designers can turn written ideas into detailed visuals, adjust fabric textures, and create more inclusive designs across sizes and styles. It’s a shift that helps fashion brands stay relevant while reducing manual design work.

AI-driven design platforms mark an inflection point for digital fashion, where creativity meets data in a single workspace.

It’s not about replacing designers but helping them focus on what truly makes each product stand out.

3. Trend Forecasting Tools

Predicting what people will want next has always been part instinct, part luck. These days, data gives teams real signals instead of guesses.

Trend forecasting tools analyze online behavior, sales history, and global customer engagement patterns to spot what’s gaining momentum.

These insights help brands manage production more efficiently and avoid overstocking fashion items that might not sell. Teams can match creative direction with real demand across both physical fashion and online markets.

Using predictive data has become one of the most valuable digital processes in modern retail. It helps brands balance creativity with accuracy and stay ahead of changing consumer behavior.

4. Digital Sourcing Platforms

Global supply chains run on communication. Digital sourcing platforms help manage this complexity by linking designers, buyers, and manufacturers in a single, connected space.

Every update, including pricing, lead times, and fabric changes, appears in real time.

These tools replace long email threads and help teams track vendor performance across continents. They create structure in an area that used to rely heavily on manual follow-ups and guesswork.

For fashion brands managing hundreds of styles, connected sourcing platforms act as a bridge between creative work and production, securing transparency across every supplier relationship.

5. Virtual Sampling and 3D Prototyping

Traditional sampling takes time and materials. Virtual samples now make it possible to visualize designs before cutting a single fabric. With 3D tools, teams view garments at scale, rotate them, and test drape and fit virtually.

It’s more than convenience. It’s a sustainability win. Virtual samples reduce waste, speed up approvals, and make it easier for teams to share ideas remotely.

3D prototyping has become one of the most practical digital tools in fashion development. It shortens lead times, lowers costs, and helps brands maintain a balance between creativity and efficiency.

6. Smart Fitting Rooms

Retail is becoming more interactive. Smart fitting rooms use sensors and virtual reality technology to create immersive and interactive experiences for shoppers. Customers can request different sizes, explore outfit pairings, or see styling options on digital screens.

These experiences connect digital and physical fashion together, which helps brands understand customer behavior beyond simple transactions. Each interaction provides data that shapes product development and future designs.

Luxury brands and retailers use smart fitting rooms to create personalized shopping moments that improve customer experience and build customer loyalty inside physical stores.

7. Digital Clienteling and E-commerce Tools

Customer relationships don’t stop at checkout. Digital clienteling platforms personalize the shopping journey across social media, e-commerce, and in-store channels. They give sales teams instant insight into past purchases and preferences.

For luxury brands, clienteling helps strengthen relationships through thoughtful follow-ups and curated recommendations. Each touchpoint reinforces the connection between brand and customer.

These systems blend digital marketing with data-driven insight, which helps retailers build trust and open new revenue streams that extend beyond traditional business models.

8. Automated Quality Control Systems

Consistency defines brand reputation. Emerging technologies in automated quality control use cameras and sensors to inspect garments during production. They flag stitching errors, color inconsistencies, and measurement issues early.

These tools cut down on waste and keep garment quality control consistent across factories. They also speed up apparel inspection, which gives teams a clear view of quality across production runs.

Fashion companies see measurable gains, such as fewer returns, smoother production, and more reliable delivery. For global manufacturers, it’s one of the clearest examples of digital innovation improving everyday work.

How Onbrand Helps Fashion Teams Go Digital

Modern fashion teams need two things in sync. A clear system to run product work and a creative workspace that moves ideas forward fast.

Onbrand covers both. One platform for product data management and collaboration. One AI design tool that turns ideas into ready-to-develop visuals. You get clarity in operations and momentum in design, without extra busywork.

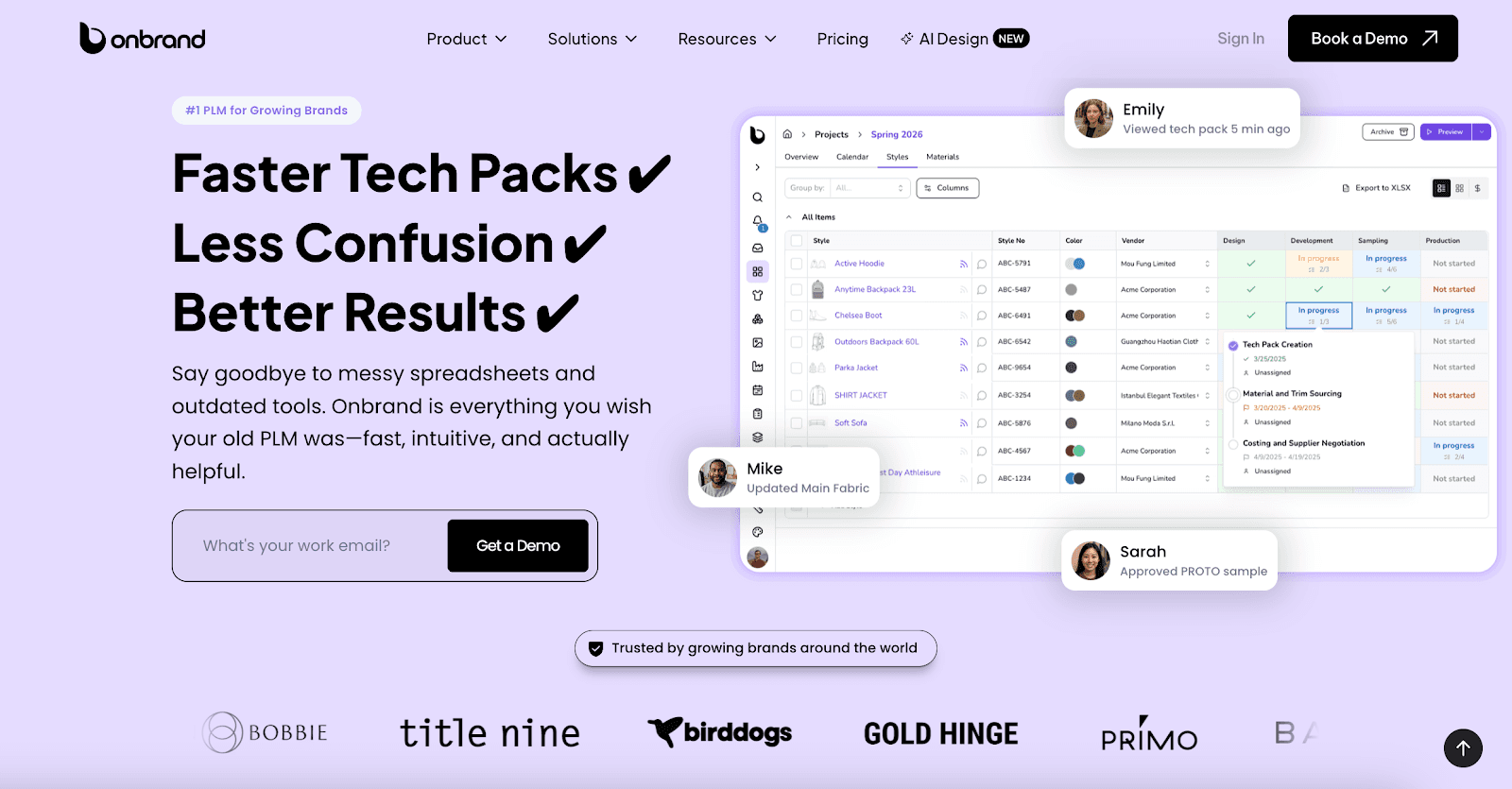

Onbrand PLM

Onbrand PLM keeps every style, spec, and update in one place. Tech packs go live, not static. Vendors see the latest details without chasing files.

Teams cut rework and move with confidence across seasons. Customers report 55% faster tech pack creation and a 4-week drop in development time.

Setup happens quickly. Data migration takes 10 days on average, then your process runs on a clean, flexible structure that fits the way you already work.

Designers, developers, and vendors stay aligned and ready for the next decision.

Key features

Live tech packs - Web-based tech packs that stay current as details change.

Version history - Full change log with easy compare and rollback.

Project management - Stages, tasks, approvals, and a T&A calendar built in.

Vendor collaboration - Factory access on the tech pack, not in emails or chats.

Dedicated libraries - Central libraries for materials, colors, artwork, and specs.

Collection planning - Plan assortments and track readiness across lines.

Sample management - Requests, status, costs, and comments in one view.

Automation rules - Auto-create tasks and reminders based on status and dates.

Integrations - Connect design apps, ERPs, and e-commerce tools to keep data in sync.

Expert support - A real team, no extra service fees, regular product updates.

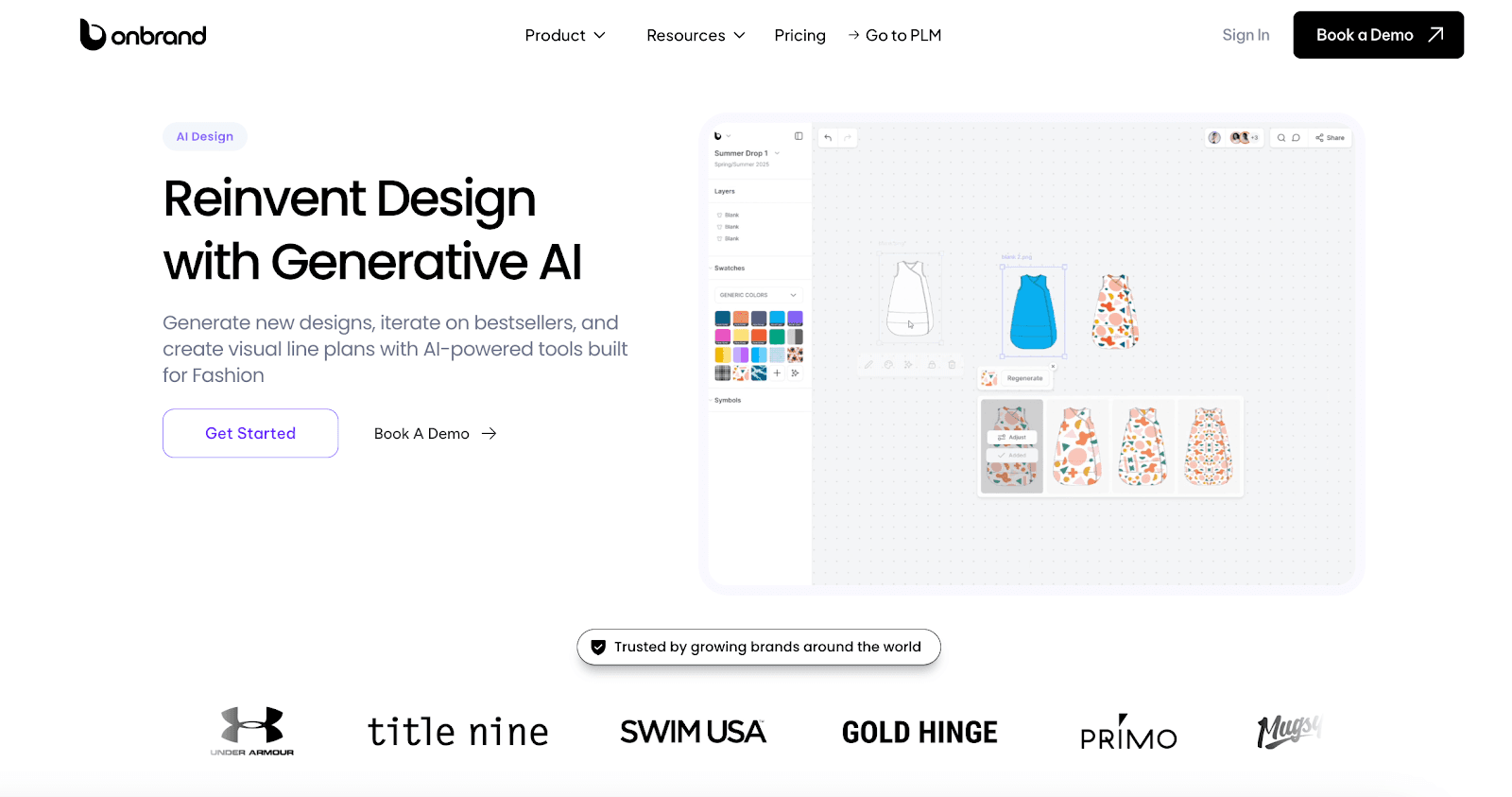

Onbrand AI Design

Onbrand AI Design gives creatives a faster path to usable visuals. Type a prompt, drop a sketch, or upload a reference.

Get photoreal options, clean flats, and on-model renders that match your category and brand. Teams report 10x faster design turnaround and 30–50% fewer physical samples.

Work side-by-side on a shared canvas. Explore colorways, trims, and cuts in minutes. Approvals stick because everyone sees the same thing.

When a concept is ready, send assets straight into PLM to start production work without re-drawing.

Key features

Generative concepts - Turn text, sketches, or photos into new design options.

Color palette engine - AI-suggested palettes, Pantone, and Coloro libraries.

Fabric and texture sims - Realistic drape and finish previews.

Auto flats and sketches - Create line art and flats from 3D views.

Real-time co-editing - Design together with comments pinned to frames.

Layered editing - Adjust sleeves, graphics, or trims without rework.

Version history - Track explorations and revert anytime.

Asset library - Store templates, graphics, and palettes for reuse.

Presentation mode - Share polished boards with notes for quick buy-in.

Connect to PLM - Export designs and details into Onbrand PLM in one step.

Together, they create a fully digital workflow from concept to production.

Onbrand replaces scattered tools with a connected system that your team actually enjoys. Designers create with confidence, developers move without delay, vendors stay aligned, and leadership sees progress at a glance.

Bring Digital Transformation to Life with Onbrand

Digital transformation is the new way forward.

Brands that adapt to connected systems and smarter workflows aren’t just working faster, they’re creating with more purpose and control. Every step, from concept to delivery, becomes clearer when teams share one source of truth and move with confidence.

Onbrand helps make that shift possible.

With Onbrand PLM, fashion teams manage product data, tech packs, and vendor communication in one place. With Onbrand AI Design, they turn ideas into photoreal visuals, explore new concepts instantly, and connect creative work directly to production.

Fashion teams using Onbrand gain a clear, modern workflow built for real collaboration and speed.

Ready to see it in action? Book a demo and learn how Onbrand helps your team work faster, stay connected, and bring every idea to life with confidence.

FAQs About Digital Transformation Fashion

What is the digital transformation of fashion?

Digital transformation in fashion is the process of using new technology to connect creative, operational, and customer-facing work. It helps fashion brands move away from manual systems to digital platforms that manage design, production, and retail in one flow. This shift creates faster communication, stronger data visibility, and better digital experiences for both teams and shoppers.

What are the 4 types of digital transformation?

The four types of digital transformation include:

Process transformation – Updating workflows with automation and connected tools.

Business model transformation – Adapting how fashion brands deliver value, such as through online-only collections that exist exclusively in digital form.

Domain transformation – Expanding into new areas like virtual try-ons or AI-driven design.

Cultural transformation – Encouraging collaboration and adaptability across design, production, and retail teams.

What are the 7 pillars of digital transformation?

The 7 pillars of digital transformation are customer experience, operational agility, data and analytics, leadership, innovation, culture, and technology integration. In the fashion industry, these pillars involve using 3D design, new fashion technology, and automation tools that create more engaging digital experiences.

What is the 7 rule in fashion?

The 7 rule in fashion refers to creating a balanced outfit using seven key elements, which are color, fabric, pattern, texture, shape, proportion, and accessories. These components work together to build a complete and cohesive look that feels intentional and visually appealing.

How are luxury brands using digital transformation in fashion?

Luxury brands use digital transformation to simplify design, improve production accuracy, and personalize customer journeys. Many adopt tools like 3D design, virtual try-ons, and data-driven product planning to enhance efficiency. Some brands, including Louis Vuitton, use digital experiences to connect physical retail with online engagement and support more informed shopping decisions.