Expert Guide to Retail Inventory Planning for Fashion Brands

Expert Guide to Retail Inventory Planning for Fashion Brands

Dec 9, 2025

If you work in fashion, you already know how much inventory decisions shape success. When stock levels align with demand, collections move quickly, margins stay healthy, and customers stay happy.

But when planning falls short, things can start to pile up both physically and financially.

Fashion teams today face shorter trend cycles, unpredictable demand, and complex global supply chains. It’s a lot to manage, and relying on spreadsheets or scattered tools only adds to the challenge.

Retail inventory planning helps bring order to that complexity. It gives your team a clear framework for what to make, when to order, and how to stay aligned across every stage of production.

When planning connects design, sourcing, and sales, your team moves from reacting to problems to making confident, informed decisions.

In this blog, you’ll learn how retail inventory planning works, what makes it effective, and how each step helps fashion teams stay organized and ready for what’s next.

What Is Retail Inventory Planning?

Retail inventory planning is the process of deciding how much stock to hold, when to reorder, and where each product belongs.

It gives your team a clear view of what’s needed for every collection and keeps you close to real demand instead of relying on guesswork.

Every decision connects back to data. When you review sales data and see how certain styles perform, you can plan ahead for what shoppers will want next.

A clear picture of inventory levels helps you act faster, avoid excess inventory, and control storage costs.

Strong retail inventory management keeps collections balanced across categories, sizes, and colors. You know which products to prioritize, when to adjust buys, and how to maintain profit margins while meeting customer demand.

For fashion brands, managing inventory means more than tracking stock across retail stores or warehouses. It’s about creating collections that sell with confidence and reflect what customers truly want.

When your creative planning aligns with accurate inventory data, your team stays ready for every season.

Why Retail Inventory Planning Matters for Fashion Brands

Retail inventory planning keeps collections profitable and efficient. The fashion industry generates about 92 million tonnes of textile waste each year, according to Earth.org, much of it caused by poor planning and excess inventory.

A clear plan helps your team manage inventory with accuracy, protect cash flow, and invest in the right products.

Reviewing sales data shows which styles perform best, allowing you to react quickly to customer demand and reduce inventory costs. With accurate inventory data, it’s easier to maintain adequate stock levels and prevent lost sales.

Effective inventory management also strengthens collaboration across design, sourcing, and retail operations.

A connected system helps every team monitor stock levels, track inventory records, and respond faster to market trends.

When planning supports customer satisfaction and aligns production with demand, you reduce waste, improve sales performance, and protect profit margins.

Strong retail inventory control doesn’t just organize stock; it builds a stable foundation for every collection.

Core Elements of an Effective Retail Inventory Plan

A solid retail inventory plan keeps your fashion business focused and balanced. Each part connects creative ideas with real data, helping you meet customer demand, manage costs, and protect profit margins.

Demand Forecasting

Demand forecasting starts with reviewing historical sales data and studying market trends to understand what customers want next. Looking at past performance helps you predict demand for upcoming collections and adjust before styles sell out or stall.

With accurate information, you can keep stock levels steady, reduce excess inventory, and improve sales performance without guesswork.

Assortment Planning

Assortment planning gives your design and buying teams a clear direction. It helps decide which categories, colors, and sizes to produce and how to distribute them across sales channels.

When you balance creative instincts with data, your collections feel current and connect with what customers actually buy.

Open-to-Buy Budgeting

An open-to-buy plan tracks how much you spend against revenue goals. Reviewing inventory records and calculating average inventory helps you plan purchases accurately and keep cash flow healthy.

With an inventory management system in place, you can see how much budget remains available for reorders or new materials before making your next purchase.

Replenishment Strategy

A clear replenishment strategy keeps bestsellers in stock and prevents slower items from piling up. Tracking inventory data and reorder points helps you maintain safety stock and avoid lost sales during busy periods.

Structured methods like vendor-managed inventory or economic order quantity (EOQ) also cut carrying costs and keep your supply chain steady.

Inventory Visibility

Inventory visibility ties every part of your business together. With a retail inventory management system or inventory management software, you can view stock levels across stores, suppliers, and distribution centers in real time.

Accurate inventory data gives you the insight to act quickly, improve customer satisfaction, and strengthen operational efficiency.

A strong retail inventory plan helps you manage inventory with confidence. It guides every decision, keeps resources aligned, and turns planning into a tool for growth.

Step-by-Step Guide to Retail Inventory Planning

Building an effective retail inventory plan starts with clear goals and organized data. Each step helps you manage inventory with more accuracy, align your team, and keep your collections moving without excess stock or missed opportunities.

1. Review Past Performance

Start by analyzing historical sales data to understand what worked and what didn’t. Look for patterns in sales trends and how customer demand shifted through previous seasons.

Reviewing these numbers gives you a baseline for setting inventory goals that support a successful retail business.

2. Set Clear Inventory Goals

Define how much inventory your brand needs to meet sales expectations without overproducing. Establish targets for turnover, stock levels, and inventory value that match your capacity and budget.

Clear benchmarks help you focus inventory investment where it matters most.

3. Align With Design and Sourcing

Connect your planning schedule with product development and raw materials sourcing. Early collaboration helps every department stay aligned, reducing delays and inventory costs.

A shared system, such as inventory management software, keeps information consistent across the entire supply chain.

4. Plan Buys Per Channel

Every sales channel performs differently, and your plan should reflect that. Review sell-through data to understand what sells in retail stores versus online.

Tracking those numbers with proper inventory management techniques helps you balance store shelves and maximize sales.

5. Track Weekly Sales

Monitor your sales regularly to measure progress and spot issues early. Use your POS systems to collect accurate data and identify slow-moving items before they affect your budget.

Tracking key performance indicators, such as inventory turnover or a metric called sales velocity, helps your team act quickly and adjust before challenges grow.

6. Adjust as Needed

Planning changes as sales trends shift. When styles sell faster than expected, use your retail inventory management work to adjust reorder quantities and maintain enough inventory for ongoing demand.

Performing physical inventory counts and reviewing category and department codes also helps keep your data accurate.

Key Retail Inventory KPIs to Track

Tracking the right key performance indicators helps you manage inventory accurately and respond faster to sales trends.

These metrics show how well your retail inventory management works and where you can adjust to maximize sales and reduce inventory costs.

Sell-Through Rate (STR)

The sell-through rate measures how much of your collection sells within a specific time frame. It helps you understand how fast products move and which styles match customer demand.

Formula:

Example:

If you received 1,000 units and sold 700, your STR is 70%. A high STR shows a strong product-market fit and reduces excess stock risks.

Inventory Turnover

Inventory turnover shows how many times stock sells and gets replaced within a season. It reflects how efficiently you manage inventory and control inventory investment.

Formula:

Example:

If your cost of goods sold is $100,000 and your average inventory is $25,000, your turnover is 4. That means you sold and replenished your inventory four times during that period, which indicates healthy demand and strong inventory management.

Weeks of Supply (WOS)

Weeks of supply tells you how long your current inventory will last based on current sales trends. It helps you plan reorder points and maintain enough inventory without overstocking.

Formula:

Example:

If you have 2,000 units in stock and sell 400 per week, your WOS is 5. You have five weeks of stock left before replenishment is needed.

Gross Margin Return on Investment (GMROI)

GMROI measures how much profit you earn for every dollar invested in inventory. It helps identify which collections generate the most value and which drain profit margins.

Formula:

Example:

If your gross margin is $80,000 and your average inventory cost is $40,000, your GMROI is 2. You earn $2 in gross margin for every $1 invested in inventory.

Stock-to-Sales Ratio

The stock-to-sales ratio compares how much stock you have against actual sales in a given period. It helps balance inventory levels and prevent excess inventory.

Formula:

Example:

If your average inventory is $50,000 and sales total $200,000, your ratio is 0.25. This means you keep one-fourth of your sales value in stock. An efficient balance that supports proper inventory management.

Best Practices for Smarter Inventory Planning

Strong inventory planning relies on clear priorities and consistent action. Each strategy below helps your team stay organized, prevent excess stock, and respond faster to real demand.

Use ABC Analysis

Start by classifying products based on value and demand. Group your best sellers under “A,” mid-range items under “B,” and low-impact styles under “C.”

Keep a closer eye on your A-group items. These often generate the majority of your revenue. Review their sales performance regularly to decide where to focus inventory investment and where you can scale back.

This method helps your team spend resources wisely and manage inventory more efficiently.

Set Reorder Points

Every product should have a defined threshold that triggers replenishment. Reorder points prevent shortages and reduce the pressure of last-minute orders.

Use past sales data to calculate when stock levels fall below safe limits, considering lead times and average weekly sales. This keeps your shelves stocked without tying up unnecessary cash in excess stock.

Maintain Safety Stock

Safety stock acts as a buffer during unexpected demand spikes or supply delays. Identify your fast-moving or high-margin items and hold a small reserve to protect sales during busy seasons.

Strong safety stock planning helps maintain steady operations, reduces lost sales, and stabilizes retail inventory costs when demand shifts suddenly.

Integrate Sales and Design Data

Your sales and design teams should work on the same timeline. Connect sales trends with new product planning to avoid repeating slow sellers or missing high-demand categories.

When design teams see what’s moving fast, they can adjust collections early. Linking creative planning with real-time performance data improves collaboration and keeps inventory decisions aligned with customer demand.

Automate Updates

Manual tracking slows teams down and increases the risk of errors. Digital tools help you update stock information instantly, keeping everyone on the same page.

Automation also saves hours each week by eliminating repetitive tasks, like data entry or version control. The result is accurate, real-time visibility into every stage of your inventory management process.

Building consistent routines and using connected systems turns planning into a predictable process. With every step grounded in data, you can make confident decisions and keep your collections moving at the right pace.

How Technology Supports Modern Inventory Planning

Every strong inventory plan starts with visibility. When you see what’s selling, what’s slowing down, and what’s waiting in production, decisions feel clear.

Technology turns that clarity into control. Modern tools organize product data, track inventory purchases, and connect every stage of your supply chain.

You can adjust faster, cut errors, and react before a small issue turns into excess stock.

Cloud systems make it easier to plan for future demand. You know what customers want, what’s in inventory storage, and when to reorder. That insight helps you stay efficient while keeping shelves stocked across stores and channels.

Retail inventory management techniques have come a long way. They now blend creative planning with live data, giving you a full picture of performance and costs.

With connected tools in place, you maintain focus, reduce waste, and enhance customer satisfaction across every step of the process.

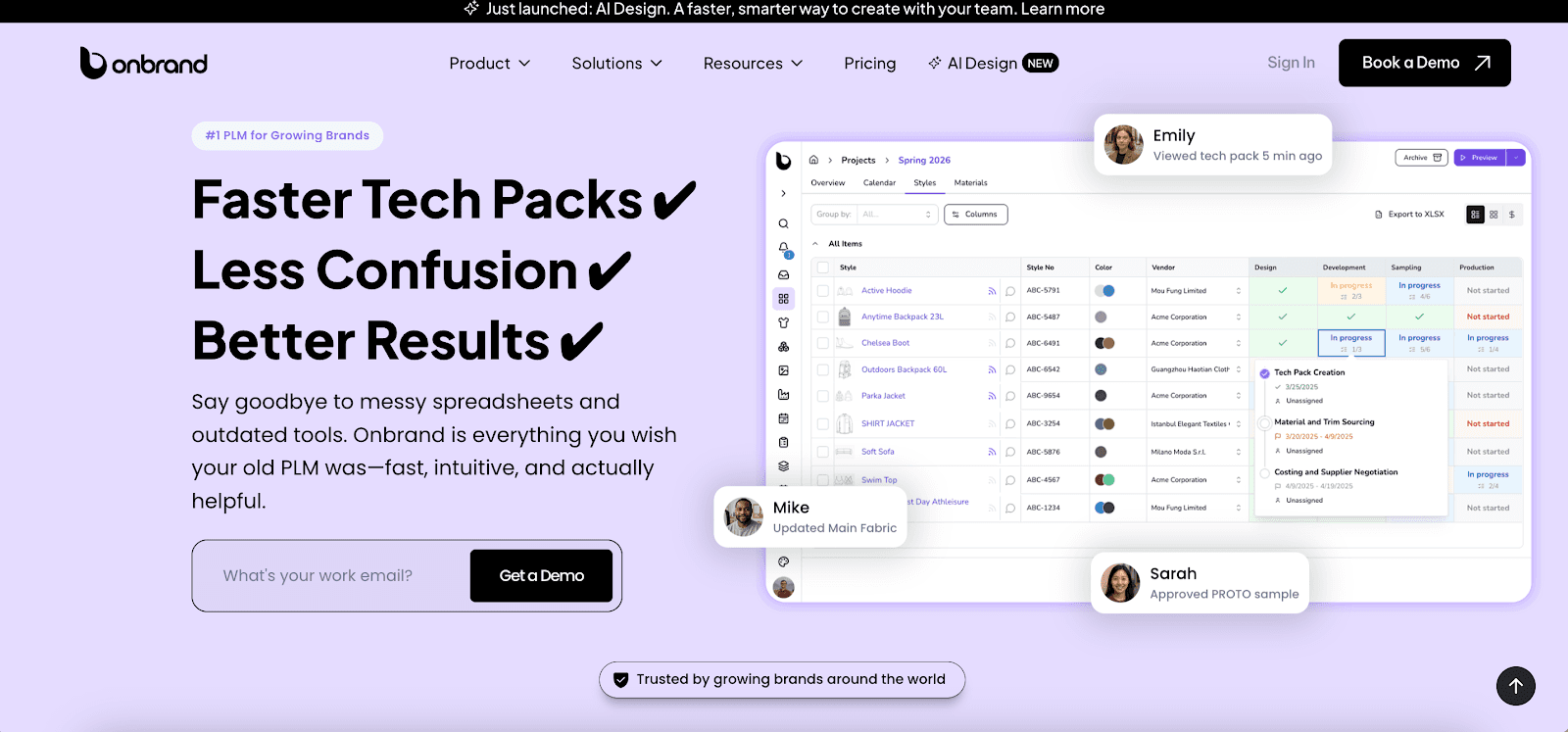

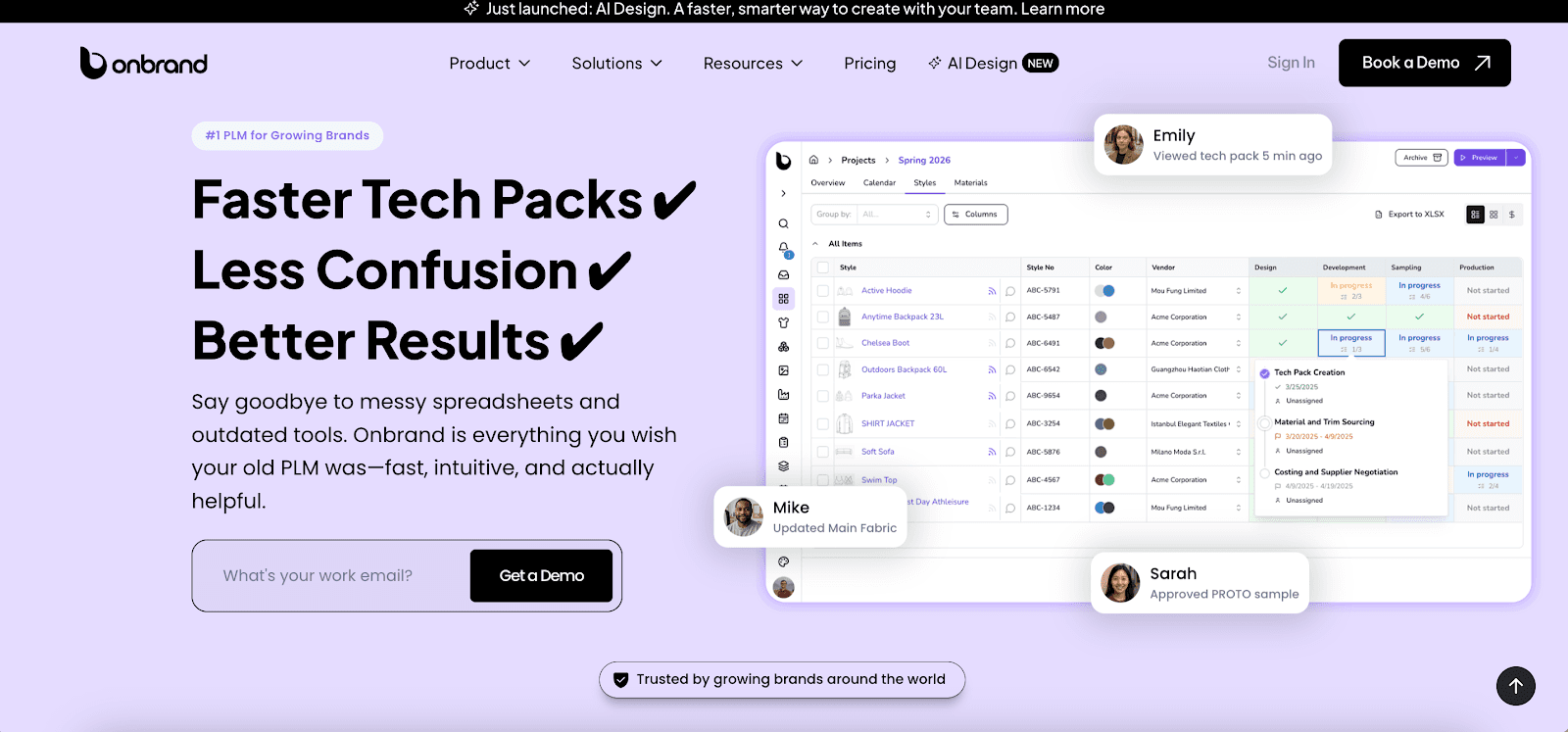

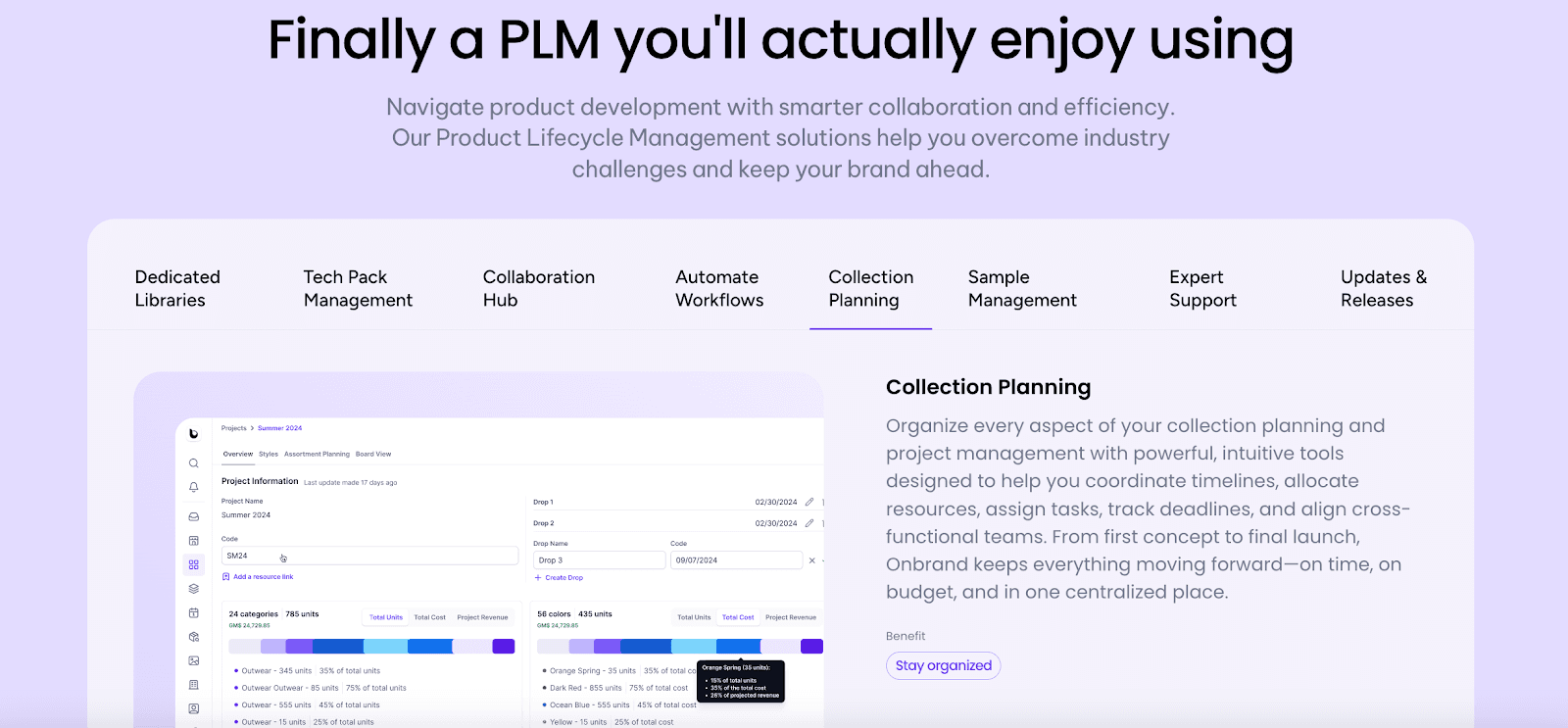

Simplify Retail Inventory Planning with Onbrand PLM

Managing collections across multiple styles, suppliers, and delivery windows is complex.

Retail inventory planning depends on accurate data and clear communication, and that’s where Onbrand PLM makes the process easier.

Instead of managing spreadsheets or waiting for email updates, every product detail stays connected and visible.

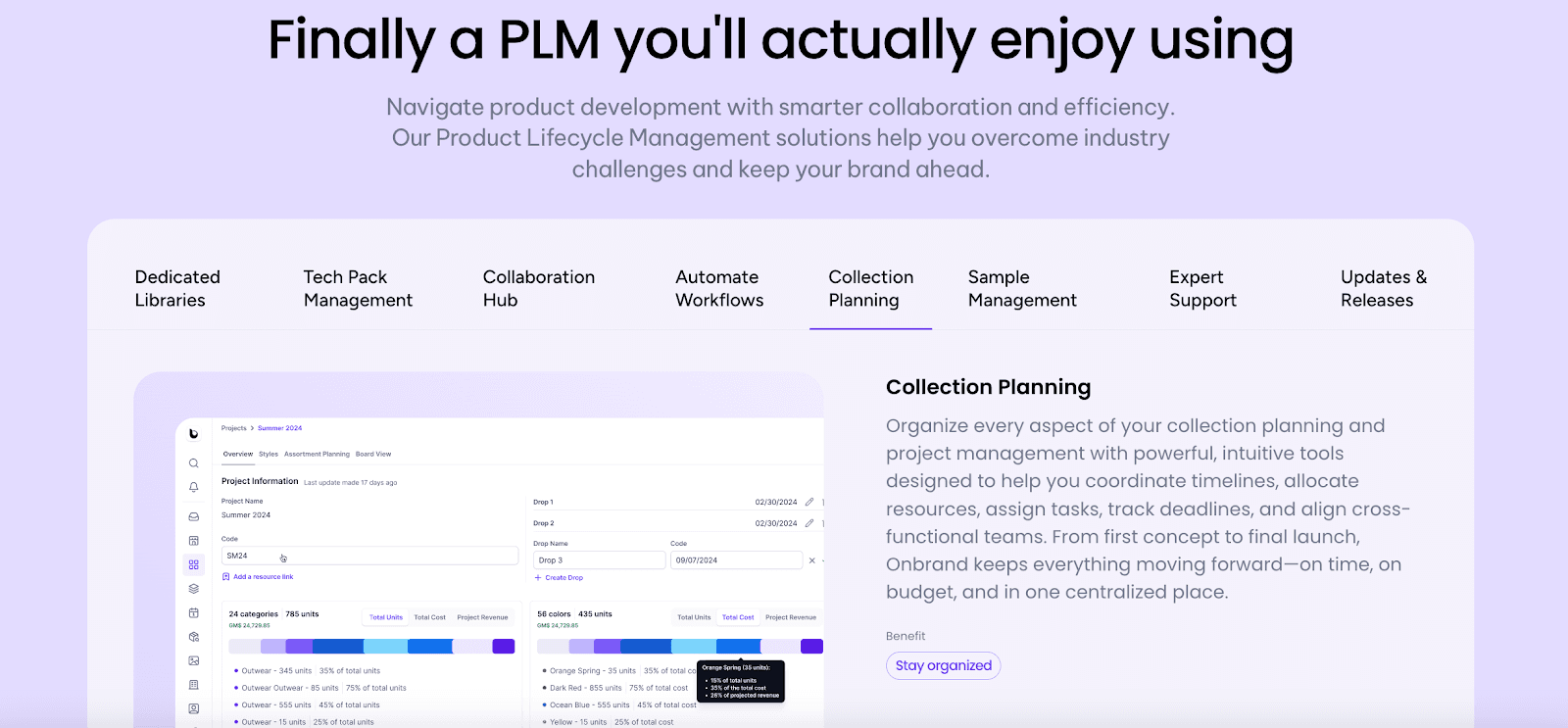

Onbrand PLM helps brands align design, sourcing and production with real numbers and timelines. Teams can view live updates, track approvals, and see progress in one place.

That visibility makes it easier to balance inventory decisions and maintain steady communication with suppliers long before production starts.

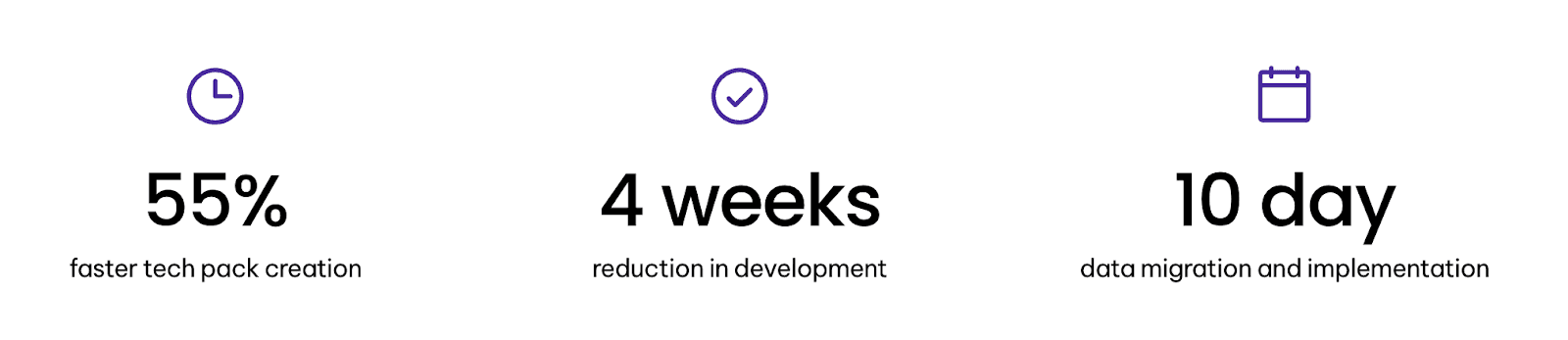

Built for growing fashion brands, Onbrand PLM is fast, flexible, and intuitive. It adapts to how your team already works, eliminating the slow, rigid setup of traditional systems.

With Onbrand PLM, product data flows smoothly between departments, helping you prepare for demand, reduce errors, and keep inventory decisions grounded in accurate information.

What Onbrand PLM Supports

Collection planning and visibility - Organize assortments, delivery windows, and product timelines in one connected workspace. Everyone stays aligned across design, sourcing, and merchandising.

Centralized product data - Manage every fabric, color, and sample in one reliable source. Onbrand keeps data consistent and easy to reference throughout product development.

Cross-team collaboration - View updates in real time and avoid version issues. You always know who approved a sample, updated a tech pack, or reviewed materials last.

Integration-ready structure - Connect Onbrand with ERP or retail inventory management systems to align production plans with sales and stock data.

Fast implementation - Most brands get up and running in just 10 days, cutting setup time from months to weeks.

Onbrand PLM gives you a foundation for smarter planning, connecting every step between concept and production. With its real-time visibility and faster collaboration, fashion brands can plan confidently, avoid costly missteps, and keep every collection moving forward.

Turn complex planning into confident execution with Onbrand PLM’s fast, intuitive platform.

Plan Smarter and Deliver Faster With Onbrand PLM!

Retail inventory planning isn’t just about numbers. It’s about creating balance between creativity and control. When every product, timeline, and decision connects, planning stops feeling reactive and starts driving progress.

The most successful brands stay ahead because they work with clarity. They know what’s selling, what’s next, and how to keep every department aligned. That level of organization turns unpredictable seasons into smooth operations and confident deliveries.

Onbrand PLM brings that clarity to life. It gives your team one connected space to plan, collaborate, and move faster together. With live data, structured workflows, and effortless visibility, it helps fashion brands design with purpose and deliver with precision.

Because when your tools work together, your entire brand moves forward.

Book a demo today and see how Onbrand PLM helps fashion teams plan smarter, move faster, and create collections with confidence.

FAQs About Retail Inventory Planning

How to plan inventory for a retail store?

Start by reviewing sales history, current stock levels, and customer demand. A clear inventory management strategy helps you balance supply and sales across locations. Using connected inventory systems gives you real-time visibility, making it easier to avoid overstock and lost sales.

What is the 80/20 rule for inventory?

The 80/20 rule means about 80% of your sales come from 20% of your products. Focusing on that top-performing group helps improve forecasting and inventory efficiency. Many grocery stores and fashion retailers use this principle to prioritize high-impact items and optimize stock rotation.

What are the 4 types of inventory management?

The four main types include raw materials, work-in-progress, finished goods, and maintenance or repair stock. Understanding these categories helps brands organize their inventory systems more effectively. Clear tracking across each type supports better planning and accurate reporting.

What is the golden rule for inventory?

Keep enough inventory to meet demand but never so much that it ties up cash flow. The goal is to maintain balance through consistent monitoring and a strong inventory management strategy. When data drives decisions, you improve turnover, reduce waste, and keep operations steady.

If you work in fashion, you already know how much inventory decisions shape success. When stock levels align with demand, collections move quickly, margins stay healthy, and customers stay happy.

But when planning falls short, things can start to pile up both physically and financially.

Fashion teams today face shorter trend cycles, unpredictable demand, and complex global supply chains. It’s a lot to manage, and relying on spreadsheets or scattered tools only adds to the challenge.

Retail inventory planning helps bring order to that complexity. It gives your team a clear framework for what to make, when to order, and how to stay aligned across every stage of production.

When planning connects design, sourcing, and sales, your team moves from reacting to problems to making confident, informed decisions.

In this blog, you’ll learn how retail inventory planning works, what makes it effective, and how each step helps fashion teams stay organized and ready for what’s next.

What Is Retail Inventory Planning?

Retail inventory planning is the process of deciding how much stock to hold, when to reorder, and where each product belongs.

It gives your team a clear view of what’s needed for every collection and keeps you close to real demand instead of relying on guesswork.

Every decision connects back to data. When you review sales data and see how certain styles perform, you can plan ahead for what shoppers will want next.

A clear picture of inventory levels helps you act faster, avoid excess inventory, and control storage costs.

Strong retail inventory management keeps collections balanced across categories, sizes, and colors. You know which products to prioritize, when to adjust buys, and how to maintain profit margins while meeting customer demand.

For fashion brands, managing inventory means more than tracking stock across retail stores or warehouses. It’s about creating collections that sell with confidence and reflect what customers truly want.

When your creative planning aligns with accurate inventory data, your team stays ready for every season.

Why Retail Inventory Planning Matters for Fashion Brands

Retail inventory planning keeps collections profitable and efficient. The fashion industry generates about 92 million tonnes of textile waste each year, according to Earth.org, much of it caused by poor planning and excess inventory.

A clear plan helps your team manage inventory with accuracy, protect cash flow, and invest in the right products.

Reviewing sales data shows which styles perform best, allowing you to react quickly to customer demand and reduce inventory costs. With accurate inventory data, it’s easier to maintain adequate stock levels and prevent lost sales.

Effective inventory management also strengthens collaboration across design, sourcing, and retail operations.

A connected system helps every team monitor stock levels, track inventory records, and respond faster to market trends.

When planning supports customer satisfaction and aligns production with demand, you reduce waste, improve sales performance, and protect profit margins.

Strong retail inventory control doesn’t just organize stock; it builds a stable foundation for every collection.

Core Elements of an Effective Retail Inventory Plan

A solid retail inventory plan keeps your fashion business focused and balanced. Each part connects creative ideas with real data, helping you meet customer demand, manage costs, and protect profit margins.

Demand Forecasting

Demand forecasting starts with reviewing historical sales data and studying market trends to understand what customers want next. Looking at past performance helps you predict demand for upcoming collections and adjust before styles sell out or stall.

With accurate information, you can keep stock levels steady, reduce excess inventory, and improve sales performance without guesswork.

Assortment Planning

Assortment planning gives your design and buying teams a clear direction. It helps decide which categories, colors, and sizes to produce and how to distribute them across sales channels.

When you balance creative instincts with data, your collections feel current and connect with what customers actually buy.

Open-to-Buy Budgeting

An open-to-buy plan tracks how much you spend against revenue goals. Reviewing inventory records and calculating average inventory helps you plan purchases accurately and keep cash flow healthy.

With an inventory management system in place, you can see how much budget remains available for reorders or new materials before making your next purchase.

Replenishment Strategy

A clear replenishment strategy keeps bestsellers in stock and prevents slower items from piling up. Tracking inventory data and reorder points helps you maintain safety stock and avoid lost sales during busy periods.

Structured methods like vendor-managed inventory or economic order quantity (EOQ) also cut carrying costs and keep your supply chain steady.

Inventory Visibility

Inventory visibility ties every part of your business together. With a retail inventory management system or inventory management software, you can view stock levels across stores, suppliers, and distribution centers in real time.

Accurate inventory data gives you the insight to act quickly, improve customer satisfaction, and strengthen operational efficiency.

A strong retail inventory plan helps you manage inventory with confidence. It guides every decision, keeps resources aligned, and turns planning into a tool for growth.

Step-by-Step Guide to Retail Inventory Planning

Building an effective retail inventory plan starts with clear goals and organized data. Each step helps you manage inventory with more accuracy, align your team, and keep your collections moving without excess stock or missed opportunities.

1. Review Past Performance

Start by analyzing historical sales data to understand what worked and what didn’t. Look for patterns in sales trends and how customer demand shifted through previous seasons.

Reviewing these numbers gives you a baseline for setting inventory goals that support a successful retail business.

2. Set Clear Inventory Goals

Define how much inventory your brand needs to meet sales expectations without overproducing. Establish targets for turnover, stock levels, and inventory value that match your capacity and budget.

Clear benchmarks help you focus inventory investment where it matters most.

3. Align With Design and Sourcing

Connect your planning schedule with product development and raw materials sourcing. Early collaboration helps every department stay aligned, reducing delays and inventory costs.

A shared system, such as inventory management software, keeps information consistent across the entire supply chain.

4. Plan Buys Per Channel

Every sales channel performs differently, and your plan should reflect that. Review sell-through data to understand what sells in retail stores versus online.

Tracking those numbers with proper inventory management techniques helps you balance store shelves and maximize sales.

5. Track Weekly Sales

Monitor your sales regularly to measure progress and spot issues early. Use your POS systems to collect accurate data and identify slow-moving items before they affect your budget.

Tracking key performance indicators, such as inventory turnover or a metric called sales velocity, helps your team act quickly and adjust before challenges grow.

6. Adjust as Needed

Planning changes as sales trends shift. When styles sell faster than expected, use your retail inventory management work to adjust reorder quantities and maintain enough inventory for ongoing demand.

Performing physical inventory counts and reviewing category and department codes also helps keep your data accurate.

Key Retail Inventory KPIs to Track

Tracking the right key performance indicators helps you manage inventory accurately and respond faster to sales trends.

These metrics show how well your retail inventory management works and where you can adjust to maximize sales and reduce inventory costs.

Sell-Through Rate (STR)

The sell-through rate measures how much of your collection sells within a specific time frame. It helps you understand how fast products move and which styles match customer demand.

Formula:

Example:

If you received 1,000 units and sold 700, your STR is 70%. A high STR shows a strong product-market fit and reduces excess stock risks.

Inventory Turnover

Inventory turnover shows how many times stock sells and gets replaced within a season. It reflects how efficiently you manage inventory and control inventory investment.

Formula:

Example:

If your cost of goods sold is $100,000 and your average inventory is $25,000, your turnover is 4. That means you sold and replenished your inventory four times during that period, which indicates healthy demand and strong inventory management.

Weeks of Supply (WOS)

Weeks of supply tells you how long your current inventory will last based on current sales trends. It helps you plan reorder points and maintain enough inventory without overstocking.

Formula:

Example:

If you have 2,000 units in stock and sell 400 per week, your WOS is 5. You have five weeks of stock left before replenishment is needed.

Gross Margin Return on Investment (GMROI)

GMROI measures how much profit you earn for every dollar invested in inventory. It helps identify which collections generate the most value and which drain profit margins.

Formula:

Example:

If your gross margin is $80,000 and your average inventory cost is $40,000, your GMROI is 2. You earn $2 in gross margin for every $1 invested in inventory.

Stock-to-Sales Ratio

The stock-to-sales ratio compares how much stock you have against actual sales in a given period. It helps balance inventory levels and prevent excess inventory.

Formula:

Example:

If your average inventory is $50,000 and sales total $200,000, your ratio is 0.25. This means you keep one-fourth of your sales value in stock. An efficient balance that supports proper inventory management.

Best Practices for Smarter Inventory Planning

Strong inventory planning relies on clear priorities and consistent action. Each strategy below helps your team stay organized, prevent excess stock, and respond faster to real demand.

Use ABC Analysis

Start by classifying products based on value and demand. Group your best sellers under “A,” mid-range items under “B,” and low-impact styles under “C.”

Keep a closer eye on your A-group items. These often generate the majority of your revenue. Review their sales performance regularly to decide where to focus inventory investment and where you can scale back.

This method helps your team spend resources wisely and manage inventory more efficiently.

Set Reorder Points

Every product should have a defined threshold that triggers replenishment. Reorder points prevent shortages and reduce the pressure of last-minute orders.

Use past sales data to calculate when stock levels fall below safe limits, considering lead times and average weekly sales. This keeps your shelves stocked without tying up unnecessary cash in excess stock.

Maintain Safety Stock

Safety stock acts as a buffer during unexpected demand spikes or supply delays. Identify your fast-moving or high-margin items and hold a small reserve to protect sales during busy seasons.

Strong safety stock planning helps maintain steady operations, reduces lost sales, and stabilizes retail inventory costs when demand shifts suddenly.

Integrate Sales and Design Data

Your sales and design teams should work on the same timeline. Connect sales trends with new product planning to avoid repeating slow sellers or missing high-demand categories.

When design teams see what’s moving fast, they can adjust collections early. Linking creative planning with real-time performance data improves collaboration and keeps inventory decisions aligned with customer demand.

Automate Updates

Manual tracking slows teams down and increases the risk of errors. Digital tools help you update stock information instantly, keeping everyone on the same page.

Automation also saves hours each week by eliminating repetitive tasks, like data entry or version control. The result is accurate, real-time visibility into every stage of your inventory management process.

Building consistent routines and using connected systems turns planning into a predictable process. With every step grounded in data, you can make confident decisions and keep your collections moving at the right pace.

How Technology Supports Modern Inventory Planning

Every strong inventory plan starts with visibility. When you see what’s selling, what’s slowing down, and what’s waiting in production, decisions feel clear.

Technology turns that clarity into control. Modern tools organize product data, track inventory purchases, and connect every stage of your supply chain.

You can adjust faster, cut errors, and react before a small issue turns into excess stock.

Cloud systems make it easier to plan for future demand. You know what customers want, what’s in inventory storage, and when to reorder. That insight helps you stay efficient while keeping shelves stocked across stores and channels.

Retail inventory management techniques have come a long way. They now blend creative planning with live data, giving you a full picture of performance and costs.

With connected tools in place, you maintain focus, reduce waste, and enhance customer satisfaction across every step of the process.

Simplify Retail Inventory Planning with Onbrand PLM

Managing collections across multiple styles, suppliers, and delivery windows is complex.

Retail inventory planning depends on accurate data and clear communication, and that’s where Onbrand PLM makes the process easier.

Instead of managing spreadsheets or waiting for email updates, every product detail stays connected and visible.

Onbrand PLM helps brands align design, sourcing and production with real numbers and timelines. Teams can view live updates, track approvals, and see progress in one place.

That visibility makes it easier to balance inventory decisions and maintain steady communication with suppliers long before production starts.

Built for growing fashion brands, Onbrand PLM is fast, flexible, and intuitive. It adapts to how your team already works, eliminating the slow, rigid setup of traditional systems.

With Onbrand PLM, product data flows smoothly between departments, helping you prepare for demand, reduce errors, and keep inventory decisions grounded in accurate information.

What Onbrand PLM Supports

Collection planning and visibility - Organize assortments, delivery windows, and product timelines in one connected workspace. Everyone stays aligned across design, sourcing, and merchandising.

Centralized product data - Manage every fabric, color, and sample in one reliable source. Onbrand keeps data consistent and easy to reference throughout product development.

Cross-team collaboration - View updates in real time and avoid version issues. You always know who approved a sample, updated a tech pack, or reviewed materials last.

Integration-ready structure - Connect Onbrand with ERP or retail inventory management systems to align production plans with sales and stock data.

Fast implementation - Most brands get up and running in just 10 days, cutting setup time from months to weeks.

Onbrand PLM gives you a foundation for smarter planning, connecting every step between concept and production. With its real-time visibility and faster collaboration, fashion brands can plan confidently, avoid costly missteps, and keep every collection moving forward.

Turn complex planning into confident execution with Onbrand PLM’s fast, intuitive platform.

Plan Smarter and Deliver Faster With Onbrand PLM!

Retail inventory planning isn’t just about numbers. It’s about creating balance between creativity and control. When every product, timeline, and decision connects, planning stops feeling reactive and starts driving progress.

The most successful brands stay ahead because they work with clarity. They know what’s selling, what’s next, and how to keep every department aligned. That level of organization turns unpredictable seasons into smooth operations and confident deliveries.

Onbrand PLM brings that clarity to life. It gives your team one connected space to plan, collaborate, and move faster together. With live data, structured workflows, and effortless visibility, it helps fashion brands design with purpose and deliver with precision.

Because when your tools work together, your entire brand moves forward.

Book a demo today and see how Onbrand PLM helps fashion teams plan smarter, move faster, and create collections with confidence.

FAQs About Retail Inventory Planning

How to plan inventory for a retail store?

Start by reviewing sales history, current stock levels, and customer demand. A clear inventory management strategy helps you balance supply and sales across locations. Using connected inventory systems gives you real-time visibility, making it easier to avoid overstock and lost sales.

What is the 80/20 rule for inventory?

The 80/20 rule means about 80% of your sales come from 20% of your products. Focusing on that top-performing group helps improve forecasting and inventory efficiency. Many grocery stores and fashion retailers use this principle to prioritize high-impact items and optimize stock rotation.

What are the 4 types of inventory management?

The four main types include raw materials, work-in-progress, finished goods, and maintenance or repair stock. Understanding these categories helps brands organize their inventory systems more effectively. Clear tracking across each type supports better planning and accurate reporting.

What is the golden rule for inventory?

Keep enough inventory to meet demand but never so much that it ties up cash flow. The goal is to maintain balance through consistent monitoring and a strong inventory management strategy. When data drives decisions, you improve turnover, reduce waste, and keep operations steady.

Discover how Onbrand PLM can streamline your product development!

Discover how Onbrand PLM can streamline your product development!

© 2024 onbrandplm.com. All rights reserved.

© 2024 Onbrand. All rights reserved.