CASE STUDY

55%

28%

reduction in end-to-end product development timelines

2 week

onboarding and

data migration

Estimated $120k+

savings annually in eliminated production errors

About

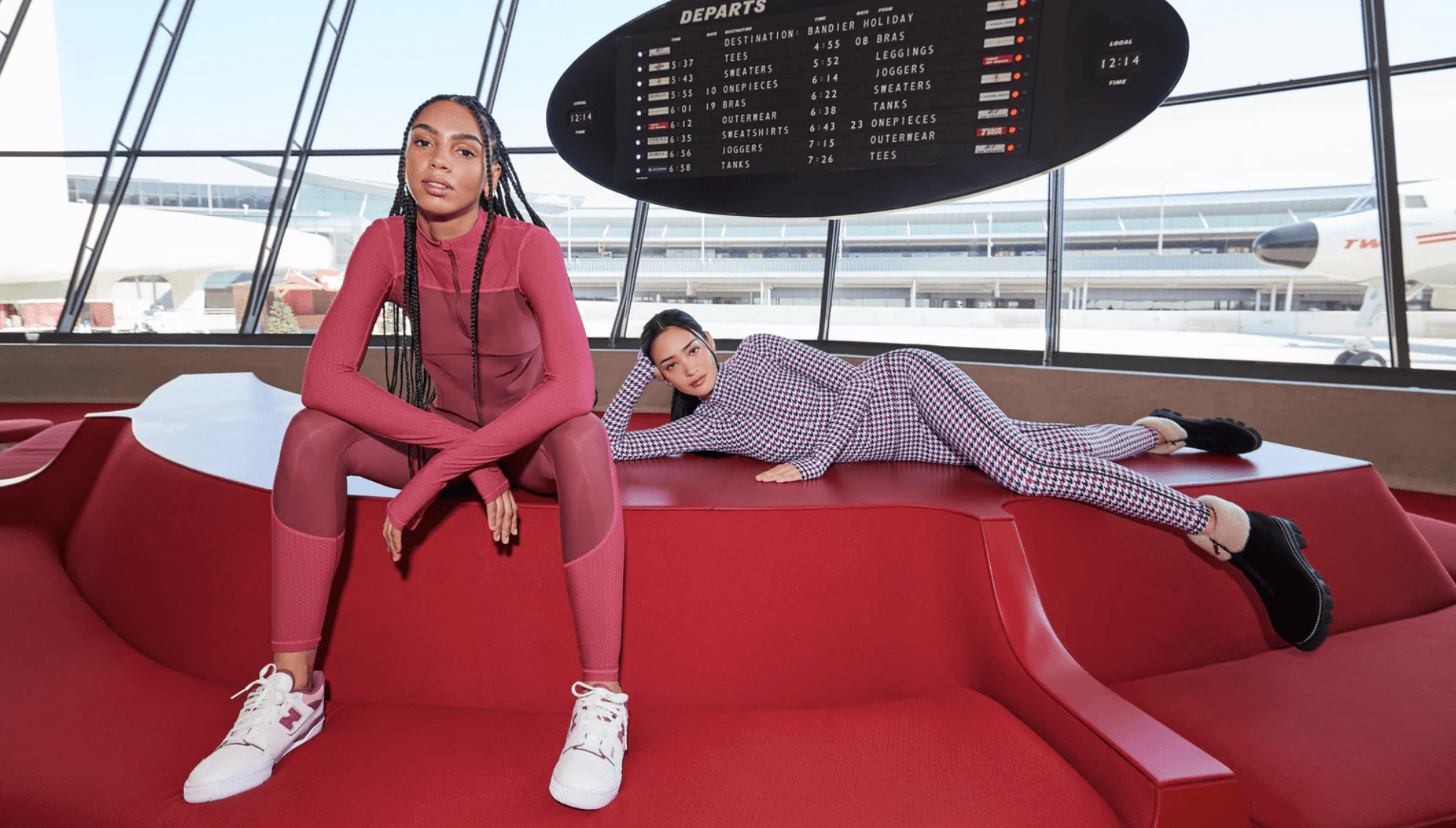

BANDIER is a leading D2C and brick-and-mortar activewear brand that blends fashion and fitness, offering premium, stylish workout gear and athleisure. Known for curating a mix of high-end performance wear and emerging activewear designers, BANDIER caters to a fashion-forward audience who prioritize both function and aesthetics in their fitness routines.

Goals

● Drive efficiency in product development to support assortment expansion

● Reduce costly errors from manual processes errors

● Find a PLM that could be implemented quickly and drive immediate impact

The Problem

BANDIER was primarily using emails and spreadsheets to manage their design and product development process and to communicate with their overseas factories. The process was manual and inefficient, leading to production delays and costly errors. Additionally, because BANDIER lacked a single source of truth, there was a lot of friction slowing down development. Danielle LaFleur, President of BANDIER and Carbon38, said, “We had a small design and production team managing three brands simultaneously and we had plans to grow from there pretty substantially. We expected to add about 50% more workload to the already strained team and we wanted to leverage technology first before adding to the team.” To support BANDIER’s ambitious growth goals, they needed a solution that could be implemented quickly so they could focus on the work they really cared about–creating great products for their customers.

While searching for a PLM solution, BANDIER identified that they needed modern software that was both effective and user-friendly. The product and design teams had extensive experience with legacy PLM tools with 12-18 month onboarding timelines and knew a better solution had to exist.

Onbrand immediately resonated from the very first meeting and it was clear that this was the right solution for them.

Danielle continued, “Onbrand really fit our needs and streamlined workflows amongst a very small but nimble product development and design team. It was clear that the product itself was very intuitive and was built by people who deeply understand the pain points of their customers.”

As an added benefit to solving the goals BANDIER set out to achieve with PLM, Onbrand also streamlined communication and collaboration with their overseas manufacturers through live tech packs and the vendor portal feature. “Streamlining communication with our factories and being able to use Onbrand as a collaboration tool was probably the biggest win,” says Danielle.

Implementation timelines played a crucial role in BANDIER's decision to choose Onbrand. In just two weeks, the team was fully onboarded and trained to use the platform. Rapid adoption followed, driven by two key factors: Onbrand's user-friendly design and, more importantly, the seamless migration of BANDIER’s data, which ensured the system was fully operational from day one.

“Across my career I've been a part of a lot of system implementations. I’ve always experienced that it's going to be five times more bumpy than what is being promised by the people who are representing the product or the solution. And this one was quite the opposite. I was expecting that it would slow down the development for the first season, but then we would see efficiencies for seasons following. We saw immediate improvement with Onbrand!”

“I've never seen an implementation that went as smoothly as this did. And I think a lot of it was really the personal care and how hands on Onbrand was throughout. I think the other piece of it is just that the product is intuitive and user friendly.”

Marjorie Schepp

“I’ve used many PLM systems before and Onbrand is by far the most intuitive. We were up and running so fast and it is saving us hours and hours a week. I never expected to be getting the benefits of the system so immediately!”

Head of Product Development